Under the Red Top

making the best of life & woodNo. 220: the legs

Prelude: The next few installments will describe the creation of a No. 220 Prairie Settle. Following a brief description of background and preparation this first episode focuses on construction of the leg components.

The allure of Craftsman furniture, regarded as America’s first true furniture form (sorry Shakers), comes from the simplicity of design and material. Graced with very few ornamental detours, the admirer is forced to recognize and then appreciate the form, joinery, wood and finish that, when executed properly, create a beautiful four-part harmony. I love the Craftsman aesthetic and have made a few pieces inspired by that style, as well as some related mission items. In most cases I have either reverse-engineered the plan from a 100-year old picture or created my own design using dimensions and joinery consistent with the style. On my last Project I stuck pretty close to the original published plan and found it a surprisingly absorbing challenge to re-create an antique. I’d like to do the same for the venerable No. 220 settle first made in 1912 by Leopold & John George Stickley, and in this endeavor I am helped enormously by the work of Robert W. Lang.

Robert Lang is a very talented woodworker, magazine editor and author who is also regarded as a specialist in Craftsman furniture. In addition, he manages an incredibly informative website. His latest passion seems to be the drawing program SketchUp which he uses to re-create plans for authentic furniture pieces. In 2013 several of his earlier books were combined into the hefty, Great Book of Shop Drawings for Craftsman Furniture. This masterpiece, since re-issued in hardcover, contains his painstakingly derived plans for many Stickley and related furniture pieces, and among these is the No. 220 settle. I don’t believe I’d have the confidence to tackle this large Project without these plans. Thanks Robert.

No. 220 plan

from: Lang, R.W. Great Book of Shop Drawings for Craftsman Furniture, Revised & Expanded Second Edition Fox Chapel, 2017.

Design

A fair description of early Craftsman settle designs might be ‘four posts, modified appropriately to accommodate the human derriere’. Endearing, yet visually crude by today’s standards, the settle was intended to provide cozy comfort to those who “settled” within its confines in an otherwise drafty room of old.

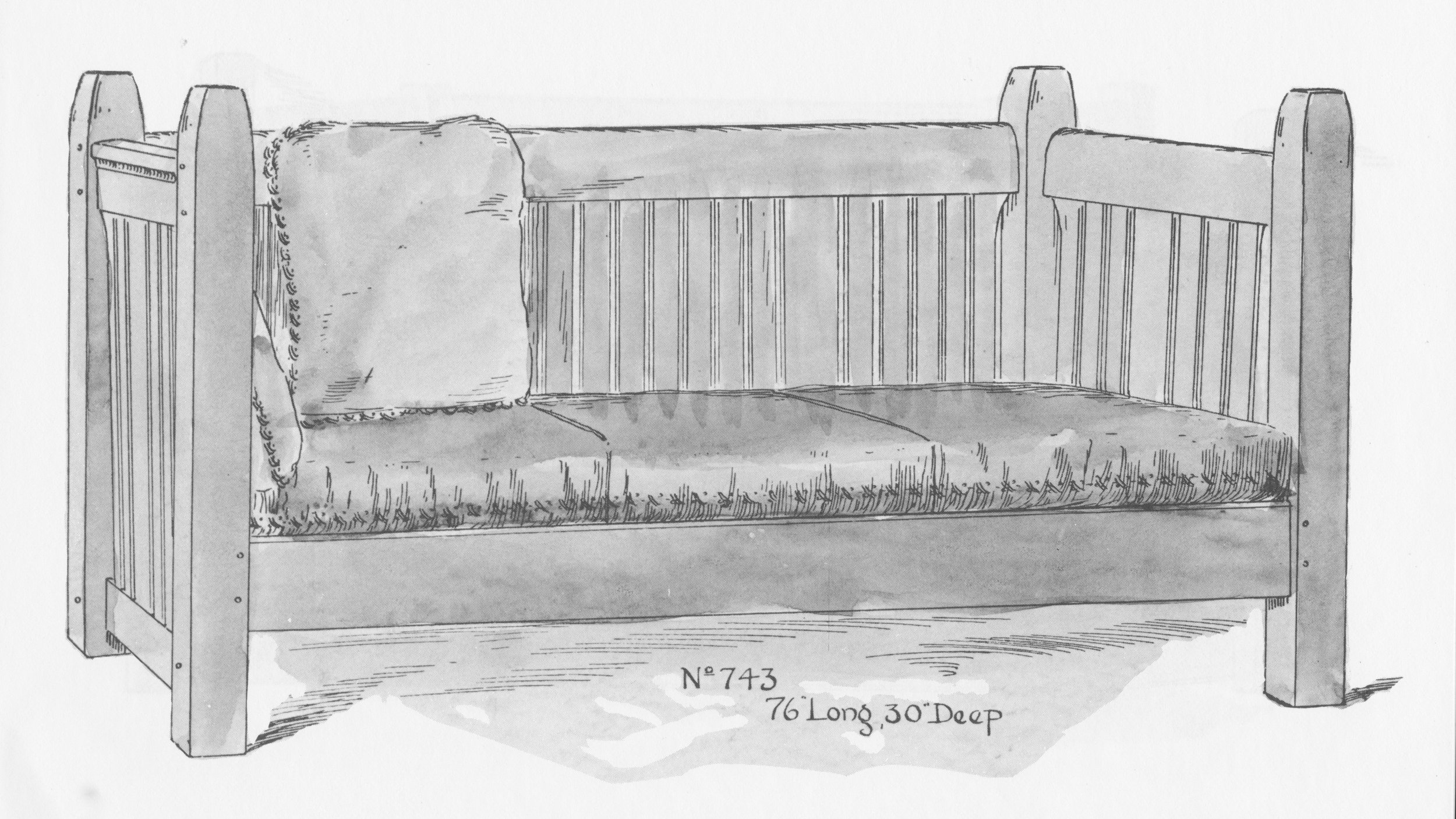

(example) No. 743 Settle

from: L. & J.G. Stickley, Onondaga Shops Salesman’s Catalog (1906), reprinted in: Early L. & J.G. Stickley Furniture: From Onondaga Shops to Handcraft, Davidoff, D.A. and Zarrow, R.L. Ed., Dover, 1992, p.61.

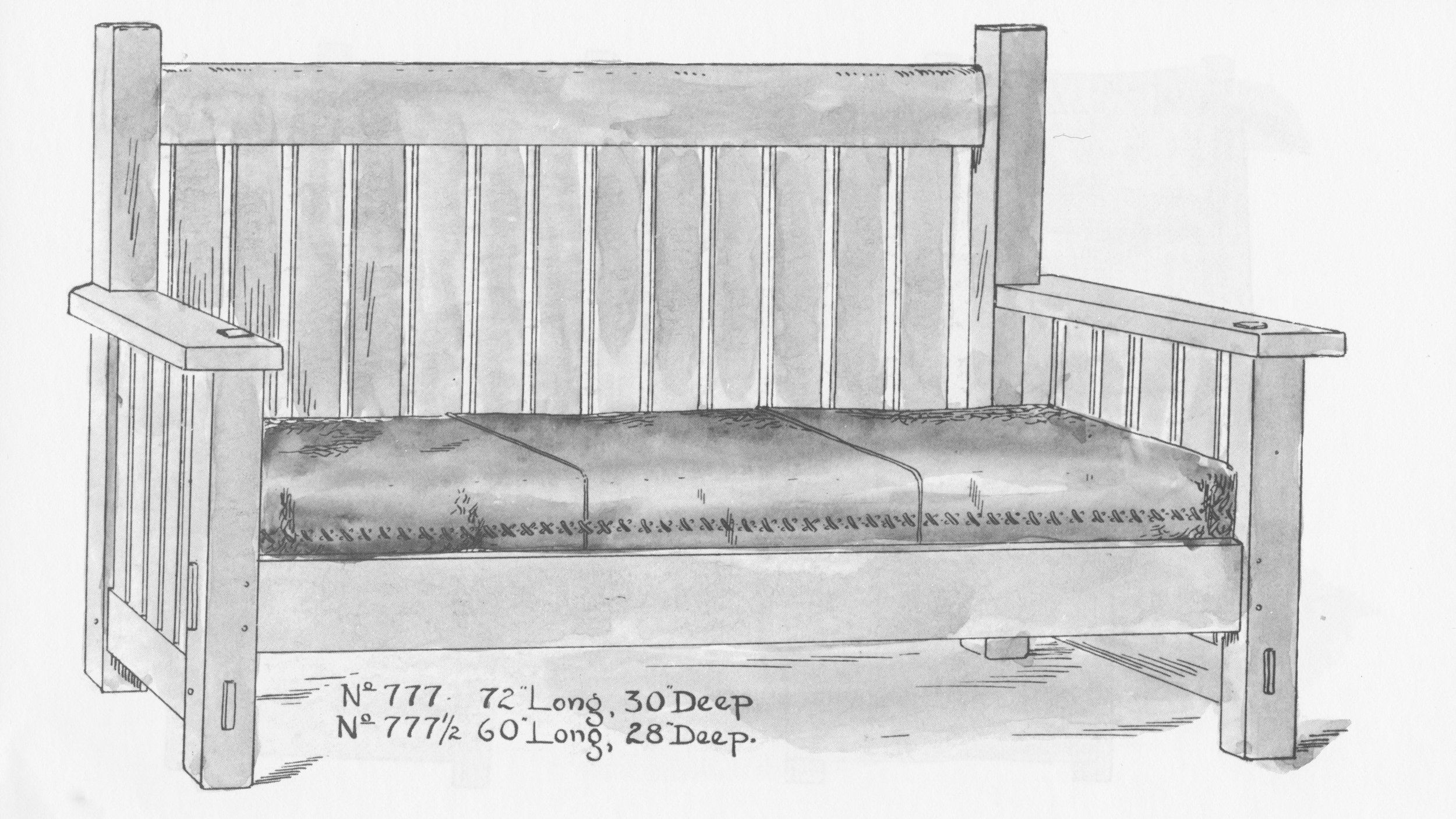

Later versions tended to separate the height of the back from the height of the side “arms”, making something that more resembles the modern sofa.

(example) No. 777 Settle

from: Early L. & J.G. Stickley Furniture, p. 77.

No. 220’s genius was to once again align the back with the arms, but this time at arm’s height, evoking the expansive Prairie sensation. The leg posts are still present to anchor the settle form, but with curvaceous corbels to support the massive arms they are no longer the primary feature.

No. 220 Settle sketch

from: Great Book, p. 150.

Materials

Although the Stickley’s offered some early pieces in a variety of woods (mahogany, chestnut, maple), white oak, quarter sawn at the mill, became the most prevalent wood used for Craftsman furniture. This abundant hardwood was the perfect material for the construction of solid furniture. Due to the orientation of the annular rings, quarter sawn lumber is the most stable form with regard to seasonal movement, and when white oak (Quercus alba) is cut in this manner it reveals the pronounced medullary rays found in this species to create a striking grain figure. Amongst all of the diagrams of quarter sawn lumber to be found in the woodworking literature, I prefer Gustav Stickley’s.

Quarter sawn lumber

Stickley, G. The Craftsman, VIII, 4, 1905, p. 109

I needed a few different dimensions for this Project and spent 2 hours picking through the quarter sawn white oak stacks for the right pieces at my favorite yard, Highland Hardwoods; 76 board-feet in all.

White oak stock

(note medullary rays evident in the center, S3S boards)

Dimensioning

While Stickley furniture legs might appear to be simple posts, simple they are not. The desire to exhibit quarter sawn grain on all four faces means they have to be specially constructed, or else gimmicked with the use of veneer. Gustav was not above using veneer for some pieces, but L. & J.G. devised a clever method to create a leg post out of four boards, fashioned in an identical manner on their factory’s machines. They even describe this innovation in their catalog, including a claim of practical indestructibility!

The Work of L & J.G. Stickley, Fayetteville, NY (c. 1914).

reproduced from: Stickley Craftsman Furniture Catalogs: Unabridged Reprints of Two Mission Furniture Catalogs, Dover, New York (1979).

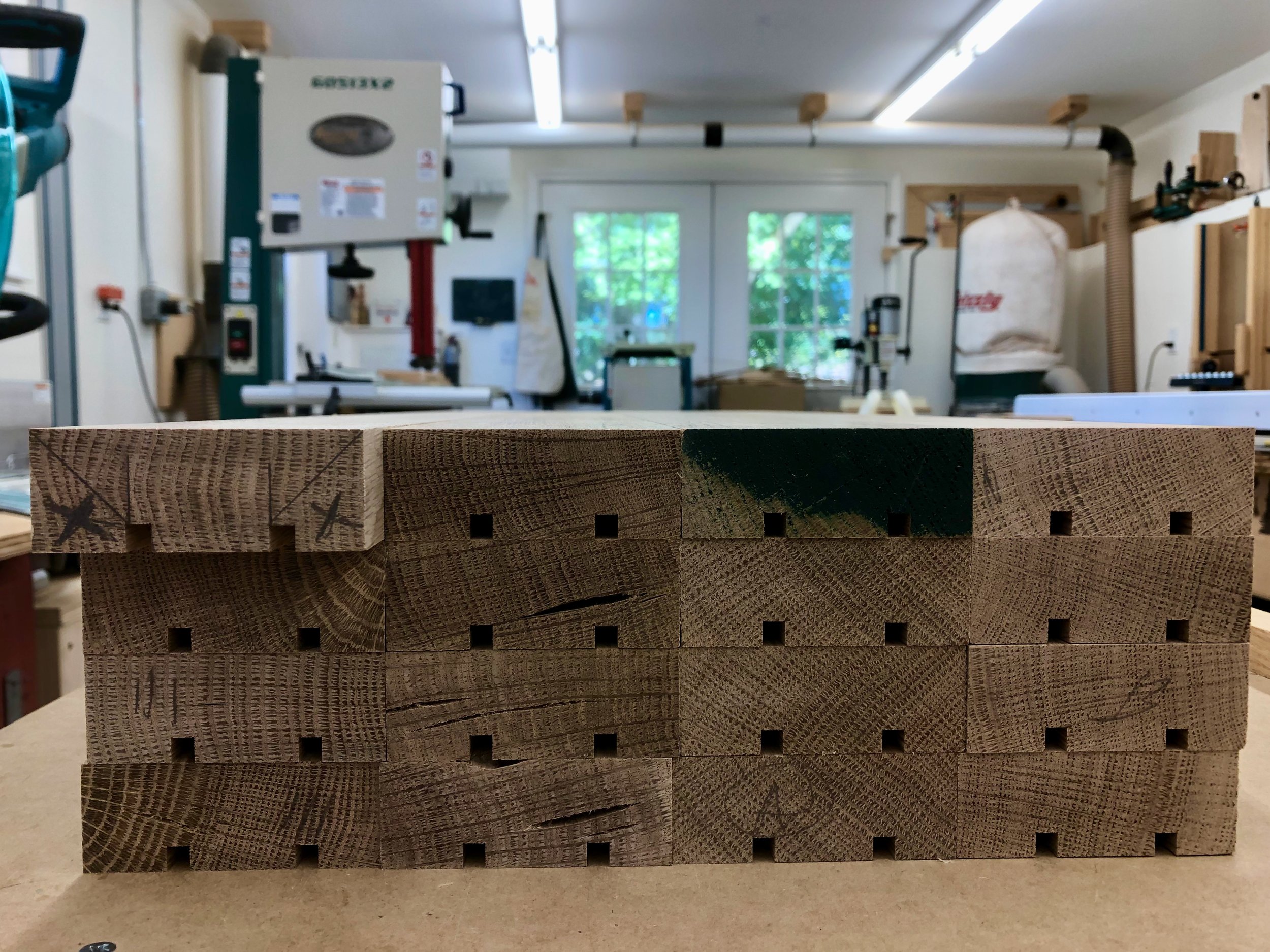

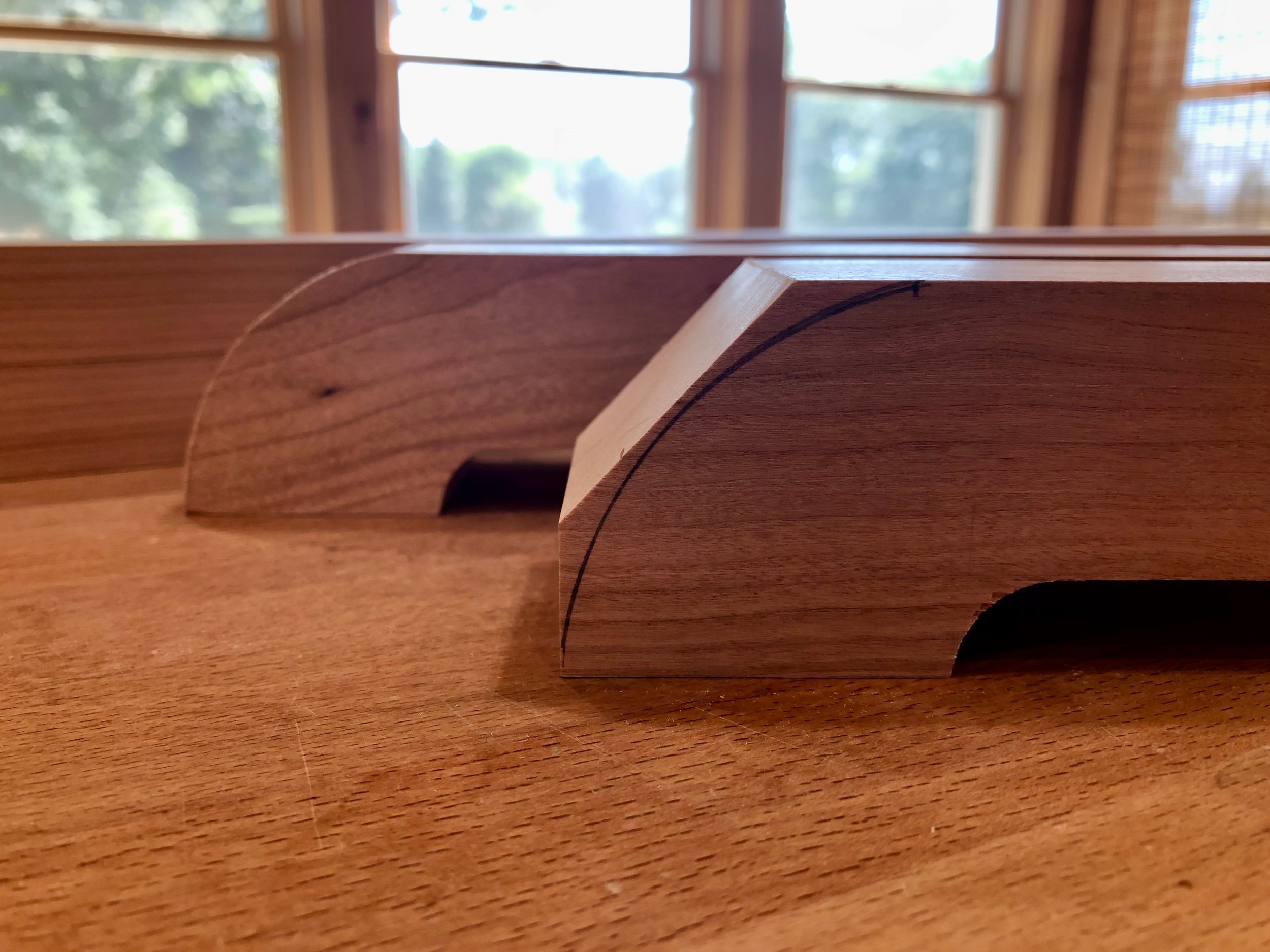

Making these so-called “quadralinear” legs begins by jointing the 5/4 rough boards square, thickness planning to 1 1/8 in. and then ripping to 3 in. widths and finally chopping to 30 in. lengths. To shape the joint, some modern day woodworkers have adopted special router bits, but I wanted to match the L. & J.G. parts. I do not have a shaper like they would have used, but Lang describes a method to make this exact leg with 4 cuts (per board) at the table saw. Details of this process are given in the Great Book, referenced above. Briefly, one creates two shallow grooves along the inside face of each leg board using a dado blade and then the portions exterior to the grooves are removed with a conventional table saw blade angled at 45 degrees. All four cuts are unique and it takes a bit of futzing to get it right. To keep things uniform it is best to make each cut 16-times in succession (i.e., once per board), and then set-up the fence/blade to make the next 16 cuts, etc. Sixty-four cuts later, all leg parts should be identical to one another and hopefully correct. Of course, you won’t know how correct until you’ve completed the 49th cut and by then you might as well just keep on cutting. I’ll use the pictures below to walk you through it.

Step 1.

Planning the cuts with a marked reference board. (Note: the 45 degree cuts meet the groove edges at different corners)

Step 2.

Cut two 1/4 in. x 1/4 in. grooves on the undersides.

Step 3.

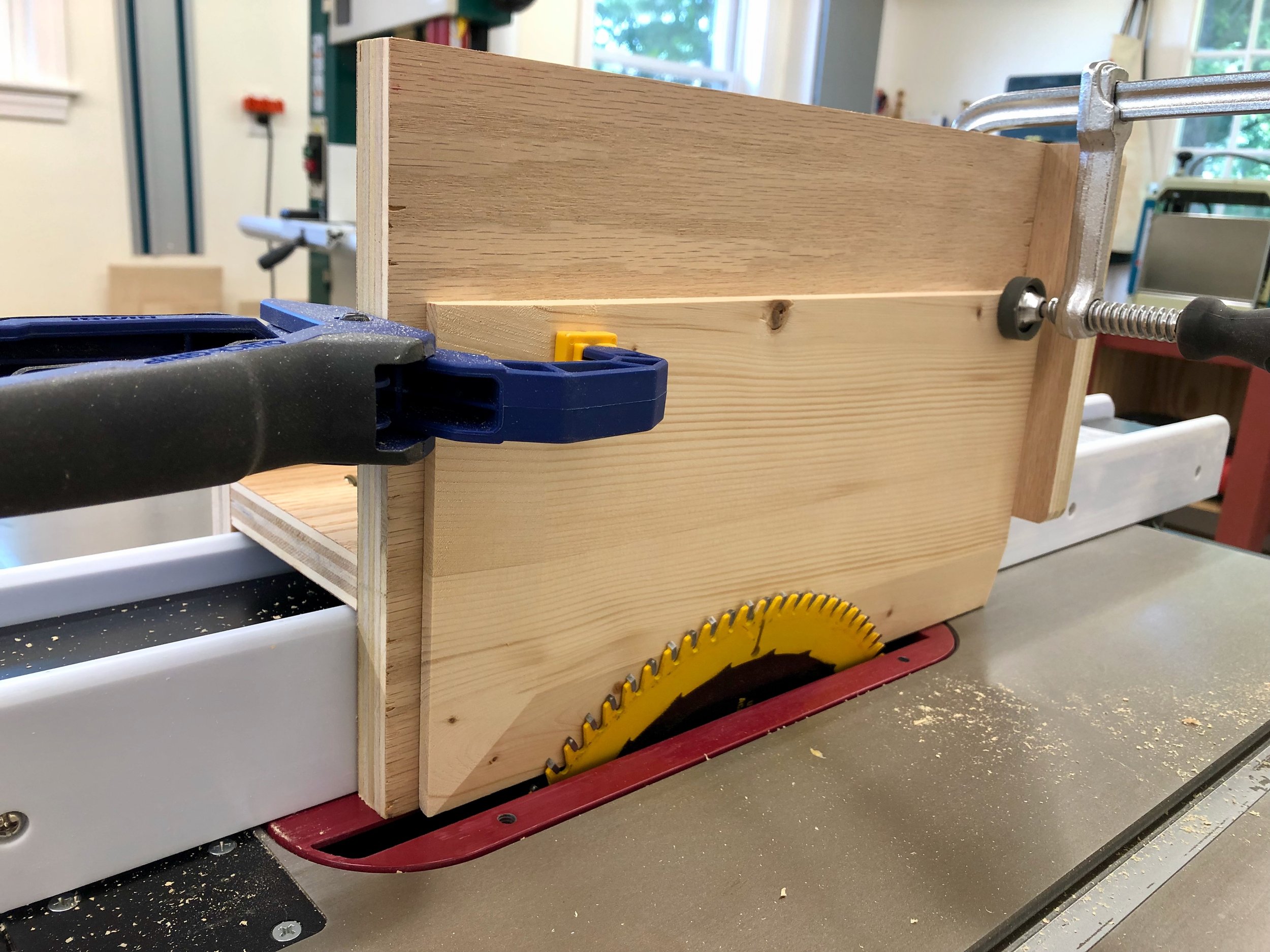

Make the initial angle cut with “show face” down and fence to the left of the left-tilting blade (re-enacted).

Step 4.

Make the final cut using a home made jig to stabilize the piece; “show face” up, fence on the right. (off-cut removed for clarity)

Milled leg parts ready for glue-up.

It took half of a day to complete but went rather smoothly. I think the home made jig, invented to shepherd the boards through their final cut, was key. During this operation the piece has a chance to wobble while riding the table on a narrow central spine and with only a thin mitered edge touching the fence. The flat surfaces of the jig riding against the fence ensure that the piece is cut nice and straight (while also keeping your hands clear of the action). The corner seams of the dry-fit legs are still not perfect, each leg exhibiting one or two thin gaps down their length, but I think when glued-up and sanded down they will look just fine. Before the glue-up I wanted to make some square “rods” to fill the central cavity within the legs. I found it was a simple task to glue together two of the triangular shaped off-cuts from step 4. to form a square-ish piece of exact length that could then be trimmed to 3/4 x 3/4 in. size on the table saw. These were tucked into the voids during the glue-up which went smoothly using F-clamps. I would need to blunt the sharp edges and fill some hairline cracks at the seams but this would best be done closer to the finishing steps.

5 boards make 1 leg.

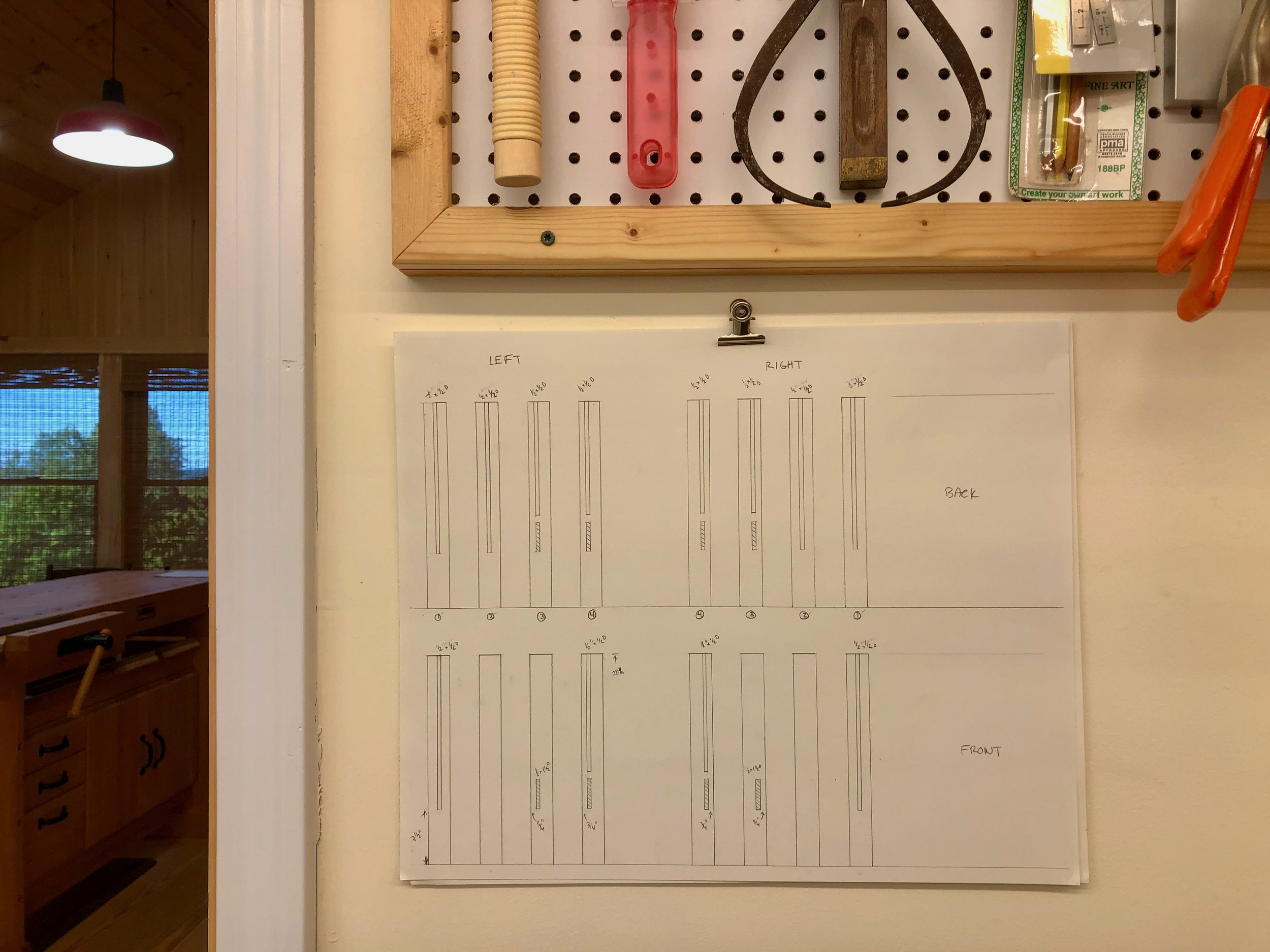

Next, the legs were trimmed to their final length at the miter saw and then a positional assignment was given to each member (i.e., Left/Front, etc). The bottom rails, panel frames and corbels all need their joint sockets cut-out at this point. The cut patterns come in pairs (2 front and 2 back) but since those on the left are the mirror image of those on the right, all four posts are distinct and care must be exercised not to make an errant cut along the way. Prior to the shop work, I took the time to sketch each leg face on paper, indicating the cut positions and dimensions with the hope that this exercise, replete with erasures, would help things go smoother in the event.

Mortice pattern hung in the workshop for quick reference

The various cuts were then marked-out in pencil on the leg pieces and the cutting was done at the mortiser and router table. Straightforward stuff, mostly. The one challenge was to mortice the 1 1/2 inch deep sockets for the front and back rails. That’s a lot of oak (read: work) for my machine so I removed some of the volume beforehand at the drill press and it made things go a lot easier. As a final step, the cavities were cleaned-up with a chisel. Their exact dimensions would be used in the next step to fashion tenons on the rails, stiles and corbels. So far, so good.

No. 220 legs

No. 220

Numbers are noteworthy. Most numbers are used to accurately record information but certain ones also define icons. I’m not referring to calendar dates or dimensional specs; rather, those numerical identifiers issued to the bearer with no other significance implied. You know the ones: 5 (perfume); 7 (spirits); 42 (baseball); 43 (NASCAR); 66 (highways); 747 (transportation); more.* They say it all, no matter the language.

* Coco Chanel’s first perfume; Jack Daniel’s original whiskey; Jackie Robinson’s uniform number; Richard Petty’s car; the first all weather route connecting Chicago and Los Angeles; Boeing’s first Jumbo Jet.

Furniture has a few numbers, too, the most famous of which might be 220. Heard of it? It comes from the days of furniture catalogs, and in particular, the catalog of Leopold and John George Stickley. L. & J.G., to use their business handles, were the two youngest brothers of Gustav Stickley, creator of the Craftsman furniture style, and who themselves operated a rather successful early 20th century furniture business. Much to their older brother’s annoyance, their catalog was packed with imitations and derivatives of his designs. But unlike Gustav, these guys stuck with furniture alone and their business, today known as Stickley Audi & Co., continues to outlast that of their benefactor’s which folded way back in 1915. L. & J.G. also made good furniture and around 1912 they designed some “mission” furniture pieces that would come to define the style. Most notable among these was the so-called “Prairie Settle”, No. 220 in their line of goods. Now, thousands of different furniture pieces were produced during this heyday of American manufacture, all numbered, and to be considered iconic among the masses an item needs to truly stand-out as a paragon. The identifying number, through continued reference, becomes synonymous with the nonpareil of that genre. (Don’t you love it when French words come through?) Indeed, L. & J.G. Stickley’s Prairie Settle has become known simply as “No. 220” to both furniture collectors and makers as a means to lift it above the many dozens of other settle variants, all possessing less enduring designs and forgettable catalog numbers.

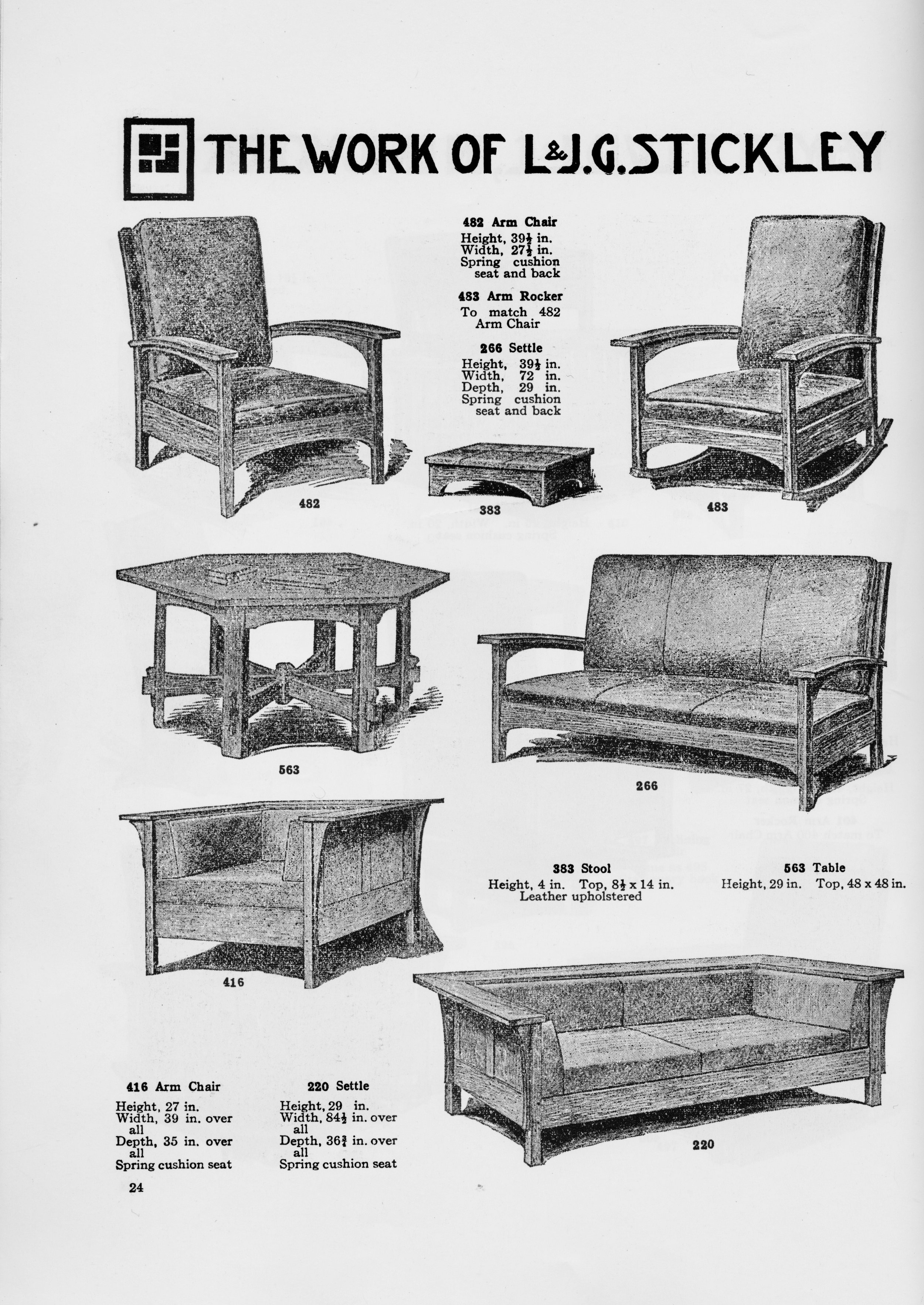

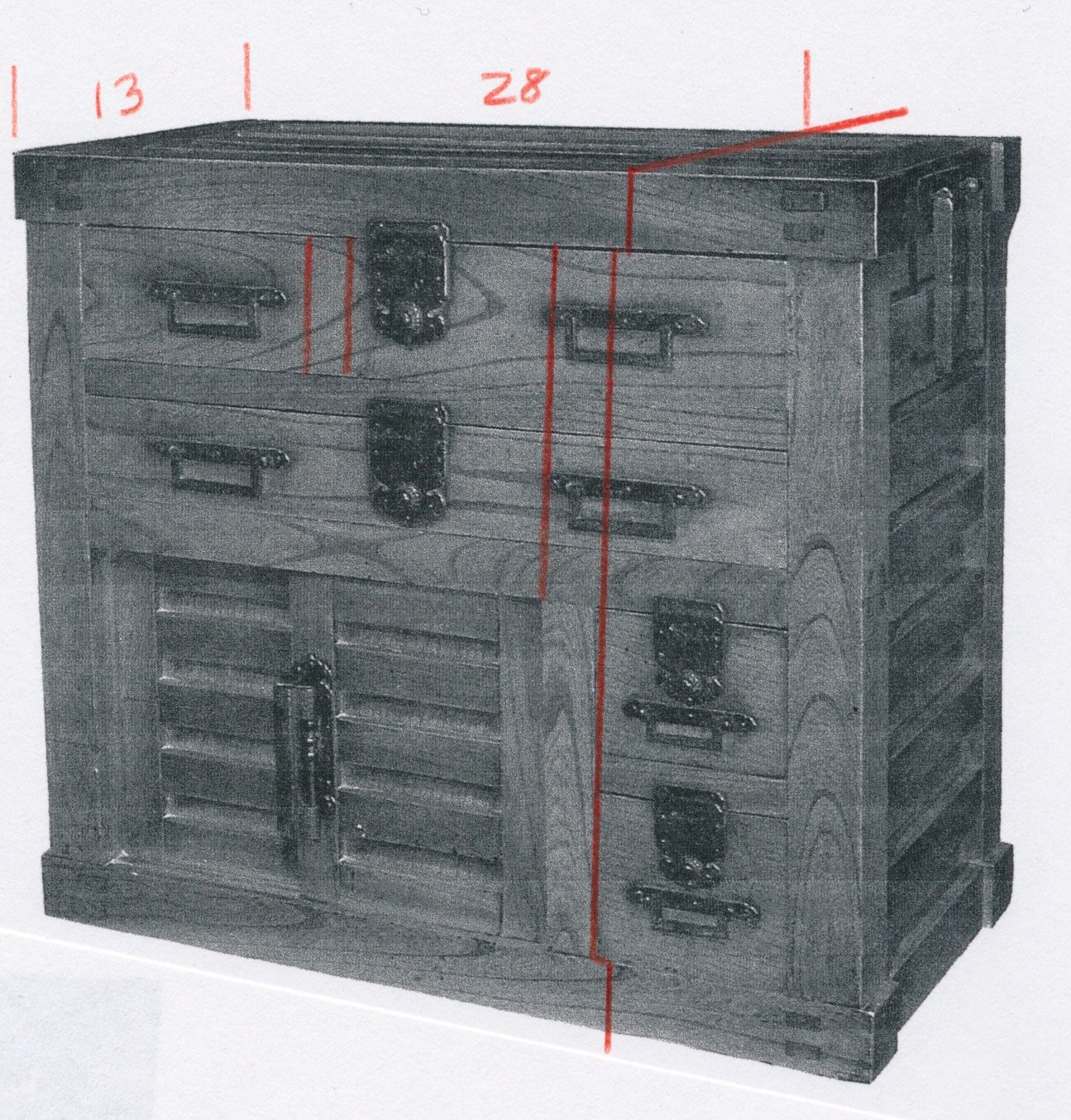

220 Settle, as displayed in the catalog: The Work of L & J.G. Stickley, Fayetteville, NY (c. 1914), p. 24.

reproduced from: Stickley Craftsman Furniture Catalogs: Unabridged Reprints of Two Mission Furniture Catalogs, Dover, New York (1979).

Sketched in pencil and buried mid-catalog at the bottom of page 24 you might wonder ‘what’s so special about this one?’. Well, this settle, and the related arm chair No. 416, contain design elements never before seen in the extensive repertoire of Mission/Arts & Crafts/Craftsman furnishings. The low horizontal lines of the substantial wrap-around arms and rectangular rails make a strong statement and are, in fact, unique. No doubt influenced by architect Frank Lloyd Wright’s Prairie School, which at that time was gaining popularity in the Midwest, these guys from New York (more accurately their designer, Peter Hansen) somehow got it right in a way that has endured beyond all others.

And by “endure”, I mean that it is one of the very few furniture items from the early 20th century that is still being produced according to the original plan. Not only can a new No. 220 be purchased from Stickley today, but a brief Google search reveals that versions of No. 220 are also available on several other furniture websites and from the artisans who market on Etsy. There are also loads of posts in the woodworking forums and blogs describing the exploits of amateur furniture makers still being drawn to No. 220’s bright porch light. You can include me in that last group, too. As my next Project, I am setting out to make the No. 220 settle for our living room. I hope you will enjoy following its progress.

Prairie Settle, No. 220

Photo by H. Peter Curran, from: Stickley Craftsman Furniture Catalogs: Unabridged Reprints of Two Mission Furniture Catalogs, Dover, New York (1979), p. vii.

Cool Costumer

Still intrigued by 100 year-old plans found in the book: Easy Mission-Style Woodworking Projects, I decided to reproduce a useful item for our bedroom while waiting for the next’s Project’s lumber to equilibrate in the shop. Here’s the story.

I have long sought a place other than the floor to stage my “in-use” clothing at night. You know, garments that are too clean to wash, but too “used” to put back into the dresser and so you plan to wear them another day. Then I read about the project on p. 45 of this former manual for middle school shop teachers titled “The Costumer” and was excited to think that a few days of effort in the Workshop and my search might be over. I reproduce that text here:

“The Costumer shown in Fig. 37 is a very good beginning problem for an eighth-grade boy. It is a large piece of furniture to the boy, and one that he will take great interest in. It is a very useful article when finished, for there is no home in which it cannot find a place, either in the reception hall or bedroom.”

Bingo!, right? Now, at first I was put off by the taunts: Beginning problem? Eighth-grade boy?, but then I remembered that the author was referring to boys from the Greatest Generation who would one day persevere in World War II to save civilization and I made my peace. Now all I needed to do was make Fig. 37 in the Workshop.

Fig. 37

from: Worst, Edward F. Easy Mission-Style Woodworking Projects, Dover, Mineola, NY, 2005, p. 45.

Design

I generally do not follow published plans in my work, but vowed to stick close with this one and, in doing so, consciously try to put myself into the world of a 1920s middle-schooler. That world was simpler, yet harder than today’s, especially outside of the big cities. At my father’s farm house in rural Michigan, life in the 1920’s meant no electricity, no indoor plumbing, no automobile (or tractor), cooking with wood or coal on a big steel stove and few conveniences. His “middle school” was the second room of a two-roomed schoolhouse that lacked, among other things, wood shop facilities. I should ask if the family owned a costumer. It was surely a different time.

Anyway, that plan is reproduced below. It looks to be a straight-forward build and the accompanying text suggests alternatives for the joinery depending on your preference for nails, screws or dowels. I’m leaning toward dowels and will probably forego the wooden clothing pegs for store-bought brass as long as the “look” can be maintained. I also intend to use electricity.

Nicely detailed “working drawing”.

Materials

Cherry wood, a new 5/4 flat sawn plank and some left-over 4/4 material from earlier Projects, would be used for the costumer. Brass hardware from FurnitureKnowledge.com would be used for the hooks.

Cherry, cherry, cherry!

Dimensioning

The finished girth of the pole and leg pieces is 2x2 in. and so the first step was to rip the 1 in. deep boards into 2 in. wide strips, flatten one face and then glue them together in pairs. This created two sufficiently thick “leg” pieces and a 64 in. log “pole”. The rough constructs were then run through the jointer and thickness planer to create square, 2x2 parts.

Starting with the legs, I first needed to relieve material from the undersides. This began by using a 1 inch Forstner bit on the drill press, to create “semi-circle” cavities near both ends of each leg.

Drilling semi-circles

The material in between the gaps was then removed at the band saw and the resulting surface smoothed with sandpaper. To round the ends of the legs I first drew the desired arc in pencil by tracing the lid of a varnish can. Next the corners were chopped-off at the miter saw and then the extra wood was carefully shaved down to the mark on a disc sander. The picture below shows the penultimate and ultimate forms.

Shaping the leg ends

The legs then needed to be connected to each other in a “cross-lap” joint. This involves cutting wood out of the central portions of both pieces: a 2 inch wide groove from the top of the lower leg; and the same sized groove from underneath the upper one. The depth of each groove equals half of the total thickness and this was found by bisecting the depth of the lower leg, cutting the groove to this depth and then using that result to mark the upper leg before cutting - no measuring. The “cutting” was done with a dado blade on the table saw assisted by my cross cut sled. Nice and clean! Next, a 1 inch square socket was created through the center of both leg pieces. Working one leg at a time, I used the 1/2 inch bit on my mortiser to cleanly cut these out.

Morticed, cross-lapped leg parts

On to the pole. The 2x2 in. pole, fashioned as described above, would need a tenon approximately 1 1/2 in. long to fit within the morticed legs. There are a few approaches to creating tenons and I had been using the dado blade/table saw method on the last few Projects. This generates a lot of sawdust but is a nice way to reproducibly make a series of identical parts. However, I only needed to cut a single tenon in this case, and that 64 in. furniture “part” deserved respect. I did not feel I could accurately and safely work the end of this pole using the table saw. The one tool in my shop that can securely position long parts is the sliding miter saw with a 5 foot table extending off the left side. These tools are normally used to cut (chop) all of the way through a board, but my tool also comes with an adjustable “stop” to hold the blade above the platen should you wish. When used as a sliding saw this feature then allows for cutting accurate grooves and dados into a board. I used this depth stop for the first time to make the four shoulder cuts for this tenon. The four rip cuts to form the so-called tenon “cheeks” were accomplished on the band saw where a ball bearing stand could be used to support the aft portion of the pole during the cut. A slot was then sawed into the center of the tenon for an eventual wedge.

The final dimensioning step was to make the four braces that support the pole. The plan called for 3/4 in. boards here but since another function of the “braces” is to lower the center of gravity, and since I would be using heavy brass hooks instead of wooden pegs up top, I decided to impart more mass by using 1 in. thick stock instead. The instructions also call for the braces to be “sawed out with the turning saw and finished up with the spoke shave and file.” I will instead be using the electrically powered equivalents: a band saw and router. While I am enthused by the nostalgia of hand tool woodworking, I feel I am still trying to get proficient with the power tools in my shop and so favor those techniques … for now. “Choice” is another luxury available today that was not present in the good old days.

For the four braces, I first prepped some 5/4 cherry stock to 1 in. thickness. I then turned to a 3/4 in. plywood scrap and rendered the desired pattern freehand with a pencil. This shape was cut out at the band saw and smoothed to the line using a drum sander to create a plywood “pattern”. The pattern was next used as a template to trace with pencil on the fresh cherry boards, taking advantage of the existing flat and square edges. These lines were “followed” on the band saw (1/4 in. blade), doing my best to stay 1/16 in. or so to the outside of the marks. To create the true curved edges I then added plywood “lips” to the bottom and back side of the pattern so that it could be temporarily screwed into the rough cherry brace along the flat edges. With the pattern on top I could then run these constructs along a flush trimming bit on the router table to create identically shaped and smooth braces (see photos below).

3 of the 4 braces shown in various stages of formation.

bottom: marked board ready for rough cut;

top: rough cut board attached to pattern jig;

center: finished brace

Cherry brace and pattern after having run through the flush trimming bit at the router table.

The braces will be glued to the pole with the help of dowels to keep everything aligned and so 5/16 in. wide holes were drilled into the pole and braces using a Dowl-it jig and hand drill. Dowels of the same diameter were then cut from a maple rod and sharpened slightly with a pencil sharpener.

The very last steps before assembly were to cut the top of the pole to form a peak, scrape and sand the surfaces and then round-off the sharp edges. The miter saw was used to clip the sides 1/2 inch from the top, as per the plan. There are two ways to do this miter cut: 1. tilt the blade to a calculated degree matching the smallest angle of a 1/2 in. by 1 in. right triangle and slice perpendicular to the pole (then rotate and chop again, four times); or 2. pivot the blade on the platen to align the laser line with the cut line and chop (rotate, etc x 4). Choice #2 appeared to be the more foolproof and after four such chops it made for a stately feature on top. All parts were then scraped and sanded to #220 grit. A small round-over bit on the router table was used to uniformly grace the edges.

Assembly & finish

The doweled construction method pretty much dictates the order of assembly on this one. First glue the dowels on to the pole, and then the braces followed by the two leg pieces. Next, a wedge was tapped into the slotted pole tenon to snug everything up. Lastly, before the glue set, screws were used to secure each brace to the legs. Three applications of a gel polyurethane finish was applied followed by attachment of the brass hooks to complete the Costumer, a worthy version of Fig 37.

Mission-style Costumer

Postscript

This was an easy & satisfying Project, and one that utilized every machine in my workshop (bolded for reference in the above story). Of course, it all could have been done as the plan intended without electric tools; instead using handsaws, hand planes, and various other blades and borers. That hand-crafted piece, just as functional, would in many ways be more valuable. The value “add” would come from the extra time and effort applied during construction, but it is unlikely the average furniture buyer would notice any difference between the two versions. That value is only realized by a knowing woodworker or furniture connoisseur who can appreciate the skills required to make things by hand.* And there’s the trap. Does a furniture maker use his/her skills to seek the admiration of peers, even at a price point that makes the product unavailable to most?, or should the aim be to maintain quality and still satisfy the many? In the early 20th century, Gustav Stickley, whose antique furniture now commands high prices, sought the latter. His factories mass produced high quality, mission-style furnishings of inspired design, “… intended primarily to fill, in the most direct and natural way, the actual needs of American home life.”** A costumer of similar design to Fig. 37 sold for $7.00 in Gustav Stickley’s 1912 catalog. Today, the Stickley Furniture Company, a descendant of his brothers’ L.& J.G. Stickley Furniture Co., sells a reissue of their 1909 version for $949.00. (sigh)

* As a collector, I would love to own a costumer made by 8th grade hands from the past century. All of its marks, nicks and unevenness would make mine look flawed by comparison.

**Craftsman Furniture Catalog, Gustav Stickley 1912, p.3.

The Clock/Diaper Bench

Yes, you read that right … clocks & diapers. Projects have been piling up here at the Workshop and any piece that can pull double duty moves right to the top of the list. Here’s the story.

Two very nice things happened this Spring to alter the trajectory of events: 1. the Rocky Mountain clock was completed; and 2. my wife and I became Grandparents for the first time. Now, these events have only one thing in common and that is they both highlight the need for more furniture in our home. You see, to keep the brass movement away from the dusty workshop during construction that clock was routinely assembled-disassembled-reassembled over the course of a couple months on a card table that sits in our “dining” room - a low surface with many other uses. Surely, a purpose-built clock bench would be useful for the next Project. More importantly, we may soon be watching our new granddaughter a few days a week and that same card table seems to be the only diaper changing station available in our recently downsized existence - again, center stage for what might be considered a behind the scene task. It’s not that we don’t have the spare bedroom space, it’s that we lack the proper furniture.

Furniture, those structures all about us that assist our daily existence, are among the most valuable things we will ever purchase without an instruction manual. While most furniture items are constructed to do a specific job, their use, assumed by the maker and implied by the form, is ultimately up to the owner. Thus, furniture leads a precarious existence. Should the need for that job ever disappear, what was once a necessity becomes dispensable and soon begins to resemble junk. Put another way, pieces that get used persist, those that don’t get the boot (vinyl covered living room sets excepted). I was reminded of this hard fact while perusing my latest library book sale find in search of clock/diaper bench inspirations. Easy Mission-Style Woodworking Projects by Edward F. Worst is a fascinating 74 page collection of furniture plans that reads today like a history book. The work is actually a Dover re-publication of chapters 1-3 from a more serious text, Problems in Woodwork, first published in 1921 as a guide for middle school “manual training” (aka shop) teachers. In it you will find obsolete? plans for not one, but TWO clothesline winders, a pen and ink stand, a shoe polishing stand, two versions of a smoking stand and the object of my interest for this Project, the telephone table. Let me be emphatic in stating there is absolutely nothing wrong with the furniture in these plans other than they had lost their purpose over time.

Inspiration for the Clock/Diaper bench

Let’s face it, the past century has witnessed a catastrophic furniture extinction. It’s a dangerous world out there and even items designed to satisfy multiple functions are not invulnerable, for example the billiard table/davenport. While I have never sat nor played a rack on one, I cannot imagine this early twentieth century item was well suited for either activity, and there’s the rub. Even when conditions are favorable (note that both billiard tables and davenports exist among us), to survive, furniture must ultimately be good at its job. With these cautions in mind, let’s move on to our Project.

Rare sighting of a billiard table/davenport

from: Mission Furniture: How to Make It, Henry Haven Windsor (1909).

Design

Admittedly, there was a pretty low risk of failure for this Project as both of its intended uses, clockmaking and child clean-up, only required a sturdy bench top surface for success. And since most of its existence will be spent unused in either capacity, the primary function of this item is to merely look good. Thus, I was searching for a classic design and, in particular, a design where “looking good” in the background was the main mission. Indeed, clock benches have a recognized form, no doubt having evolved to suit a clockmaker’s vocational needs and comfort. But they look kinda “boxy” and, at 42 inches in height, are too tall for diaper changing work. Store-bought diaper changing tables, of which we were a proud owner some 30 years ago, also have a recognizable form. Ours was a three drawer chest fashioned from spray painted particle board onto which was snapped a vinyl covered pad. The problem is that neither of these fully functional items look particularly attractive when not in use. And that’s what clicked for me when I came upon the plans for a telephone table. Back in the day, the job of this furniture item was to sit near the wall where the telephone plug was mounted, support the phone and provide a table and seat for the telephone user. We had a telephone table in our home while I was growing up. I recall we never talked on the phone unless seated at this table, and we rarely sat at that table unless we were on the phone. Our telephone, on a party line with a neighbor down the road, was rarely used and so, although vital for its mission, that telephone table sat in a corner of the kitchen and for the bulk of its life simply tried to look good. Its 1940s design was that of a modified chair, but earlier models were more like slender desks and something that could be easily modified to serve a clock/diaper bench function. The exemplar for our Project is that item on the far left of the book cover, above. I reproduce the nicely detailed plan for this table below, although since all of the dimensions were being enlarged it was of little practical use. I just like the nostalgia of the candlestick telephone rendered lightly in its intended position (upper left).

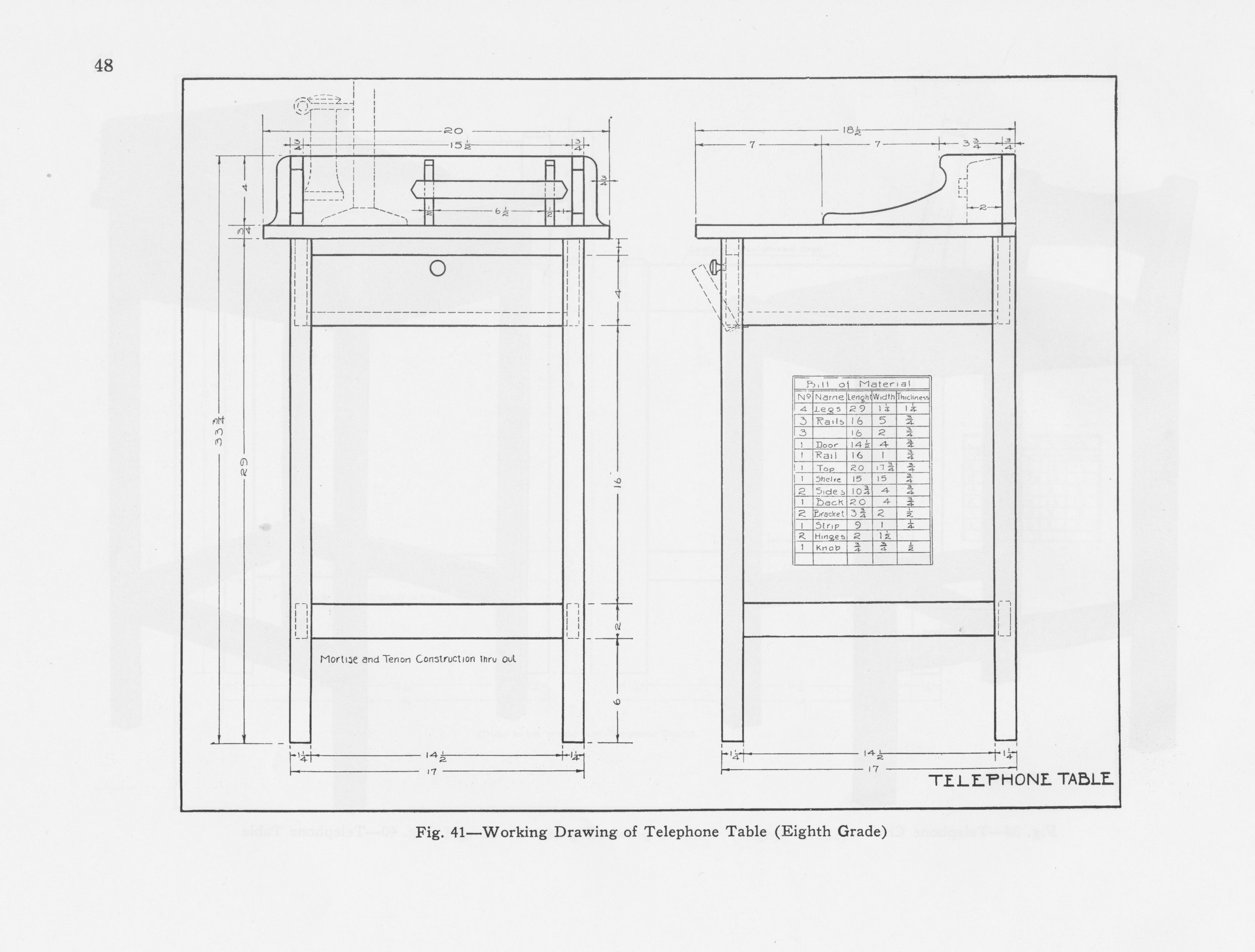

Plans for a telephone table.

from: Worst, Edward F. Easy Mission-Style Woodworking Projects, Dover, Mineola, NY, 2005, p. 48.

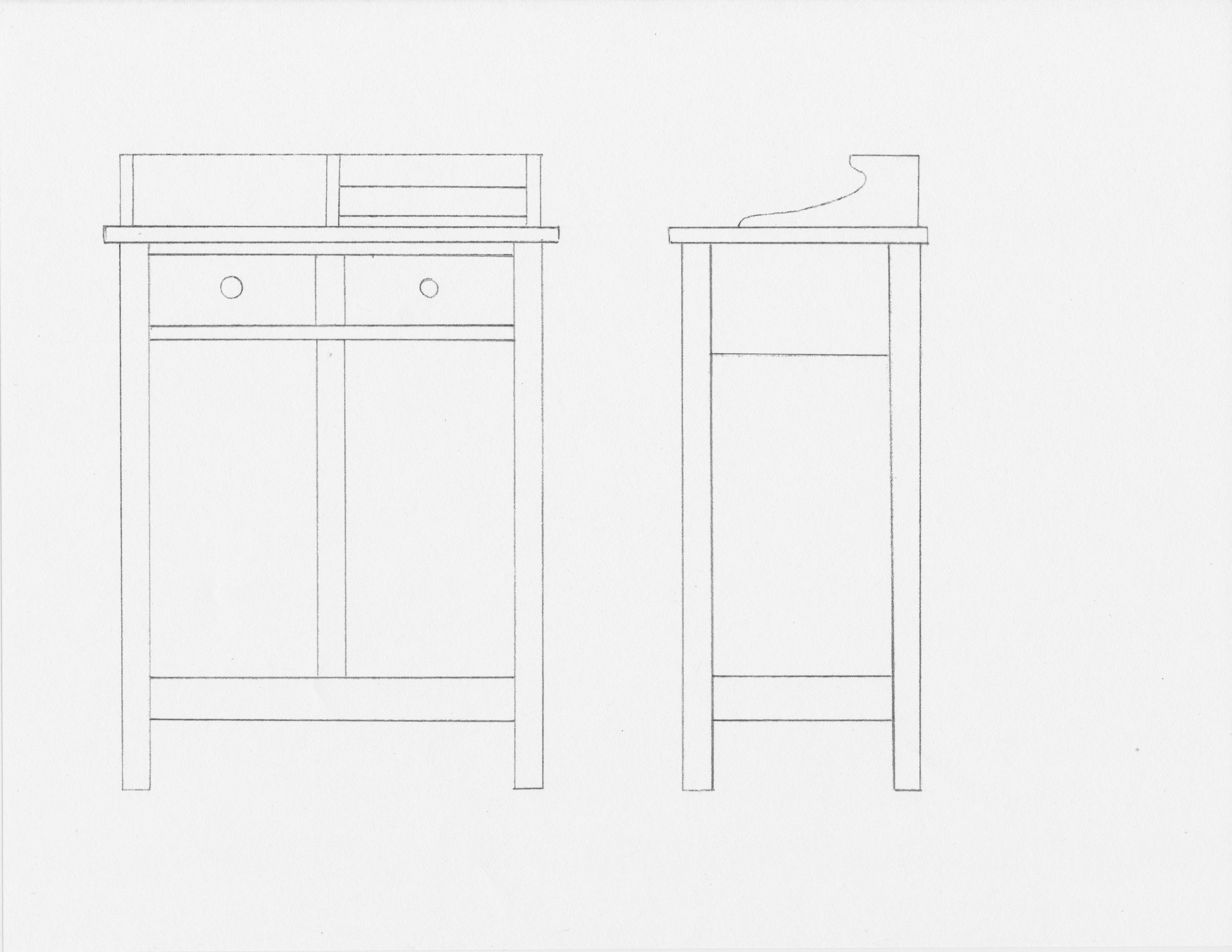

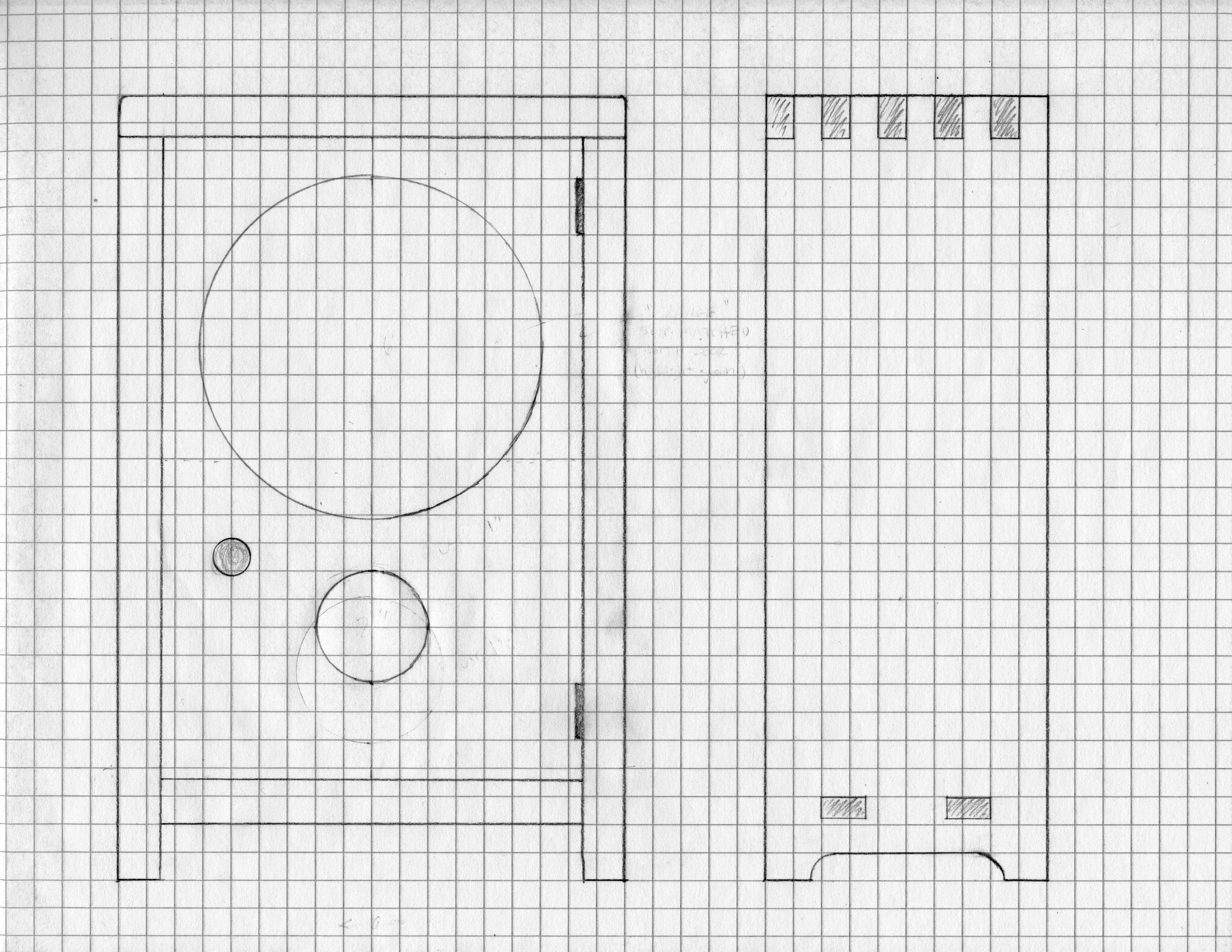

The book’s plan includes a hinged door compartment for stowing the telephone book (as your Mom), whereas ours would include a fully functional inset drawer here - two drawers, actually. My rough plan, below, kept the 42 inch clock bench height but this was reduced a few inches during construction to avoid having to also make a step stool for the diaper changer’s use. I kept the open leg work but added a vertical brace in the center. Looking good so far.

Clock/Diaper bench plan

Materials

In keeping with the tradition of mission furniture the original piece was done in quarter sawn white oak. I also wanted some nice solid hardwood for this piece but was not married to oak. Since time was of the essence and I had recently “workshop equilibrated” some cherry and ash boards for a Korean shelf project, I thought these could be nicely re-purposed here instead. In particular, I had some 4/4 quarter sawn cherry boards that should make for nice and stable leg parts. The table top would come from a 5/4 ash specimen, also with tight and uniform grain. 4/4 Cherry flat sawn boards would be used for the remaining external parts and various oaks and poplar for the draw components. I found some turned Shaker knobs for the drawers to complete the piece in keeping with the original design.

Cherry planks marked for cutting

Dimensioning

When making tables I like to start with the legs. In the end they will be the least conspicuous element, but during construction that’s where all of the joinery occurs. Our square legs would be 2 x 2 in. but since my boards were only half of this width they would first needed to be thickness planed, ripped and edge joined together. These were then smoothed with the scraper and cut to 35 in. length - as mentioned, a bit shorter than planned but a more convenient height for diaper operations. They would now be heavily morticed to accept the top and bottom rails that would connect it all together. This process can be made simple by adhering to common distances throughout: 1/4 in. set backs; 5/8 in. mortice depth; 1/2 in. wide tenons, etc. A few stop blocks and some forethought as to the order of operations and it all comes together rather easily. The tenoned pieces were fashioned last so that they could be formed to exactly match the width of the morticed openings. This was done at the table saw with a dado blade and then parred further with a shoulder plane to get a nice, “squeaky” fit. To join the center “post” I decided to use dowels instead of tenons. I always wanted to try my Dad’s old Dowl-it (no “e”) doweling kit and found that it worked smooth and accurate for this purpose. A very convenient contraption invented in 1949 and still in production, today.

The Dowl-it self-centering drill guide in use

The parts were then smoothed with a card scraper and readied for assembly.

All 15 leg parts ready to go.

I decided to use 3/4 in. plywood as a bottom shelf for the drawers to run on and this would be attached by pocket screws to the frame elements during assembly. The other interior parts assisting drawer operation were made out of scrap oak pieces. For the table top I cross cut a beautifully figured 5/4 ash board in half, thickness planed to a uniform 1 1/8 in. depth and edge joined the two pieces with the aid of wooden biscuits. This was then smoothed and cut to final dimensions with a track saw.

Glueing ash to form the top

Assembly & Finish

I chose to assemble the frame at this point, even though the trim elements for the tabletop would still need to be made. This would let me get started on the drawers, and the bench could also be carried back into the house for emergency diaper use should construction go slow. First, two legs and their connecting stretchers were glued together - one set in the morning and then the second set directly on top of that one in the afternoon. This maneuver lets me be sure that they are identical to one another.

Glueing the second leg assembly, templated on top of the first

Glue-up of the entire frame was accomplished the following day, employing extra assistance from my wife to limit the potential for catastrophe. These pieces can get both heavy and unwieldy towards the end of the tenon pounding & clamping process, but glue doesn’t care. The interior drawer parts were then cut from oak and glued/screwed in place.

Frame intact

Next came the drawers. I bought an extra 4/4 cherry board from a local yard and this would furnish both the drawer fronts and trim along the tabletop. The drawers were put together with the rabbeted half-dovetail joinery used in recent projects. It’s a clean, quick and easy method that yields a handsome product. You recall the sequence: [fit the drawer front; create the box and bottom; futz with the carcass dry fit; glue and dowel the drawer parts together; keep on futzing until you like the way it all looks and operates] x 2. Enjoyable work yet I sometimes wonder if we pay cabinetmakers enough.

Drawers complete

The final element is the trim on top that creates a border for the back and sides of the workspace. This was made from 3/4 in. cherry boards using finger joints to mate the corners. The shop-made finger joint jig used for the Rocky Mountain Clock served nicely here. First the trim’s back board was cut on both ends and then the two sides were taped together and the fingers cut-out in a single session.

Both side trim pieces being cut as one using the finger joint jig.

These side pieces, still taped together were then cut to a pattern on the bandsaw and finally made smooth with a rasp and sandpaper. To me this simple curve, copied from the original plan, evokes both the style and innocence of the 1920’s. Biscuits were inserted along the back to assure a uniform and secure attachment of the trim to the table top, and that top was then secured to the upper legs by way of four figure 8 “table irons”. Finally, a hole was drilled in each drawer front for the knobs.

Dry fit table trim

To prepare the piece for finishing, a light, whole body hand-sanding was conducted. This removed extraneous clamp marks and gave a uniform surface all around. The piece was then sealed and preserved with 3 applications of (satin) gel polyurethane. This coating is very durable and, to me, it is the best way to finish cherry wood without concern for splotching. The knobs, obtained on Amazon.com via China, were of some unidentified hardwood and, while each sports a different grain pattern(?), I decided to leave them alone and not stain them any darker. The existing color contrast of the ash and cherry was enough without adding a competitor. It seemed to work. Following a final (cloth) diaper buff the 1920s telephone table turned clock/diaper bench was complete.

Now, let’s put it to use.

The Candle Box

Some very old and dear friends of ours just purchased a very old home (the oldest, actually) in a very dear little town just outside of Boston. You think we’d be glad, and we were. However, this happy event presented us with a quandary: what to bring as a housewarming gift to a house that’s been “warming” for 275 years? Something solid, sturdy and timeless of course, but avoiding actual furniture yet staying within the bounds of a household accessory, what serves? From the title of this post you already know the solution but please read on.

It is hard for modern Americans to imagine life during Colonial times, when the original portion of this house was built, but it would do us all some good to try. Contemplating history helps to put today’s troubles in perspective and can even evoke pride in our ability to solve problems and overcome hardship. One of my favorite authors, Matt Ridley (biologist, journalist, viscount and former member of the House of Lords), published an interesting book a few years back called The Rational Optimist: How Prosperity Evolves. It is worth a read (and re-read) whenever you feel the need for a dose of perspective. On page 20 Ridley touches on the subject of lighting, specifically how much better we have it today than in times past. Comparing the tallow candles of 1800 to the compact fluorescent bulbs of 2010 and using average working wages for those periods he computes that one hour’s worth of reading light in 2010 costs 1/2 second of labor, whereas this would have required over 6 hours of work in that earlier time. Think about that. And since that comparison was made we’ve moved on to even more efficient LED bulbs. Prosperity evolves! Despite life’s ever present travails we need to appreciate how easy the act of living has become, and smile more often.

Where is this heading? Well we now understand how valuable candles were during Colonial times. In the days before paraffin, candles were generally made from a matter called “tallow” (hard fat) obtained from cattle and sheep, and a lot of effort was expended between pasture and parlor to create the one-and-only appliance that allowed us to see after dark. Once purchased (or made at home) candles needed to be both conserved and preserved. To make them last, they were continually snuffed out and relit, or carried from room to room. And to keep them from being devoured by house mice when not in use they were stored in wooden boxes. Aha!, the candle box.

Design

Candle boxes go back a long way and over time their form had differentiated to serve two distinct functions: 1. long boxes to store brand new tapers; 2. short boxes to store the mostly used but recyclable “stubs”. The simplest examples operate without hinge or hardware, using a sliding top to gain access to the contents inside. That’s the design we will use. Joinery was generally done by dovetails on the corners and the use of either pegs or nails to secure the bottom. This box will be patterned off of a design from a recent library book sale find, Country Pine by Bill Hylton. The dimensions used fall midway between the long and short boxes described therein and were dictated by constraints in the starting material (see below).

Materials

Like the originals, this box will be made out of pine. Specifically, old white pine that I had purchased a few year’s back from a guy named Craig on craigslist. Craig lives in Maine and buys centuries-old, dilapidated buildings there. He then carefully dismantles these structures and resells the wooden parts to people like me. In my “old wood” collection I found a 7 foot long tongue and groove panel and a piece of resawn barn timber that should serve our purpose, nicely. The panel contains nail holed introns spaced 16 inches apart, but good wood could be extracted from the exons in between (scientist talk).

Antique pine lumber.

Dimensioning & Assembly

Once it was decided exactly where along the 7 foot plank the box sides, top and bottom would be extracted from, the rest of the wood prep was straightforward: rip the edges to remove the tongue and groove milling; crosscut the sections to remove the nail holes; joint two edges flat & square; rip to exact widths; thickness plane to 5/8 in. (sides), 1/2 in. (lid), 1/4 in. (bottom); and then crosscut to exact lengths. It’s a sequence that varies little from project to project, yet never gets old. The lid and bottom pieces would be fashioned from two smaller boards each, first edge-glued to create a wider “board” and then cut to the desired dimensions prior to assembly.

Candle box boards

Next comes the fun part, cutting the through dovetail joints. First, a few final design specs needed to be fixed. The box sides are 3 1/2 in. tall and I decided that two dovetails would be used to join this span. The dovetail joint locks the so-called “pin” and “tail” elements together, and the remaining dimensions in play relate to the width of the pin and the angle of the tail. There are some general norms here associated with the era of construction (like men’s neckties, pin widths oscillate in and out of style) and the type of wood (softwoods such as pine call for a larger tail angle than hardwoods) but since there will be minimal stress on these corners it really all comes down to aesthetics. I chose the maximum width of these pins to be 3/8 in., and tails angled at 10 degrees, or a 1:7 pitch. The two long side boards were then marked on each end for the tail elements, clamped together and sawn as one. This was the first time I tried this joiner’s shortcut and it worked pretty well. I also made the cuts with a Japanese Dozuki pull saw for the first time. On softwoods these saws create nice clean lines with very little effort, I have to say. The other steps all went as planned, more or less, but are not detailed here. Suffice to say I still have a ways to go if I ever want to get good at dovetails.

Disassembled dovetailed box

The boards glued-up nice and square, and with a little hand planing, patching and sanding it made a solid box body. Next, the bottom board was cut slightly generous to the box perimeter dimensions and affixed using small finishing nails. The edges were then hand planed smooth and equivalent to the box sides.

The box lid will rest on top of the sides and needs only a groove in which to ride. I chose to “create” that groove by joining “L-shaped” trim boards along the top of three sides of the box. These were made at the router table by rabbeting excess side board stock. They were then mitered at the corners and affixed with glue. Probably not the way it was done in olden days, but the truth is I needed to work around some nail extraction damage in my antique pine and this was a simple fix: cut the wood up and then piece it back together.

After trimming the lid board to the correct width, three sides were beveled to create narrowed edges that would fit within the groove. To achieve the bevel I made a new panel raising jig for my table saw based on one described by Norm Abram (host of PBS’s New Yankee Workshop (1989-2009) and inspirational figure to self-taught furniture makers everywhere) in his book, Mostly Shaker from the New Yankee Workshop. This jig straddles the table saw rip fence and allows one to safely pass the panel to be beveled through an angled table saw blade. Works nice, and using an 80 tooth precision blade it yields a surprisingly clean surface which was then touched-up with sandpaper.

Panel raising jig in action

Once the lid was sanded and running smoothly within its track the final step was to create a finger pull. This meant entering the world of wood carving, or at least sampling the experience. Chiseling a partial cone into the soft pine lid seemed like a simple task but none of my flat edged tools could do the job. I needed a new gouge, of which I found there were plenty of styles, profiles and manufacturers to choose from. I was looking for the baby bear implement here (not to big, not too small, not too curved, etc), and after consulting with a son and nephew, who both do this stuff well, I settled for a tool of #6 curvature in an 8mm width. It worked great for this application and will no doubt be a useful size for other small furniture applications.

Finger pull and gouge

Finish

The final step was to finish the pine. Original candle boxes almost certainly would have been covered in milk paint, but modern sensibilities favor the look of wood. And the grain on this old pine is so captivating that I decided to go for an “unfinished” look. A single coat of satin gel polyurethane was applied on the exterior surfaces to highlight the changing grain colors, ward off fingerprints and achieve a bit of water-proofing but the internal cavity was left untouched. With a light steel wool buff that old pine felt like velvet and I decided to stop right there. After all these years it still has an eau de terpene air and seems eager to patinate again, in its new home.

Antique pine candle box …

at home.

Clock of the Westies

Clock of the Westies … get it? (all you Pop Rock fans of a certain age). Its meta-meta to be sure, being a pun on a famous spoonerism of the familiar saying “West of the Rockies”. It also describes my latest Project.

The occasion is the July wedding of my nephew Spencer to his lovely mate, Julia. They happen to reside west of the Continental Divide in Durango, CO which is where this “destination” wedding (for us) will occur, and my wife and I decided to gift them a clock to commemorate the event. Now, clocks are not traditional wedding gifts but they could become so in our family as Uncle Mark enjoys making them and he has no shortage of eligible nieces and nephews. Let’s see how this one goes.

Design

First, a bit about clocks. I like to explore Mission style clocks of the early twentieth century. I admire their “honest” appeal. Eschewing the intricate carving of German pieces, the stone and metalwork found in many French clocks, and the fancy moldings of early American designs, their essence is a simple profile and the seductive texture of wood. They also keep time, of course, but timekeeping was merely table stakes for marketing clocks during their heyday. The popular trends were set, and continually reset, by the case design. (Not unlike marketing automobiles on their chassis appeal.) For this Project I spent some time designing shelf clocks inspired by the Mission styles of the New Haven Clock Co. but decided in the end that these were still too made-up, too fancy. In my mind, a Rocky Mountain clock case needed to be plain-spoken and natural; in a word, “rugged”. But a rugged object that could still appeal to the eye. Going back to Arts & Crafts basics, I then conjured a modern version of the iconic Stickley mantel clock and found it to be both compelling and make-able. My guiding principle was: thou shalt not distract from the wood. A few changes were proposed in this case compared to Stickley’s design. Instead of a dodecagonal face with numerals, this one would be round and numberless (think Movado museum watch). I could also echo the round clock face opening with a circular pendulum reveal, common in other Craftsman and Shaker cases. A rough plan was drawn on graph paper but I was prepared to tweak all dimensions once the clock movement arrived and vital measurements could be made.

Materials

Butternut was the lumber chosen for this piece. This wood, Juglans cinerea, works easily and is remarkably soft considering its close relation to black walnut, Juglans nigra. With its dramatic grain and subtle orange-brown tones, butternut is the wooden equivalent of tanned leather. A single, 5 in. by 8 ft. plank of 4/4 stock should be all it takes to make the case. The clock face would be made of a less figured wood (TBD).

Butternut clock stock

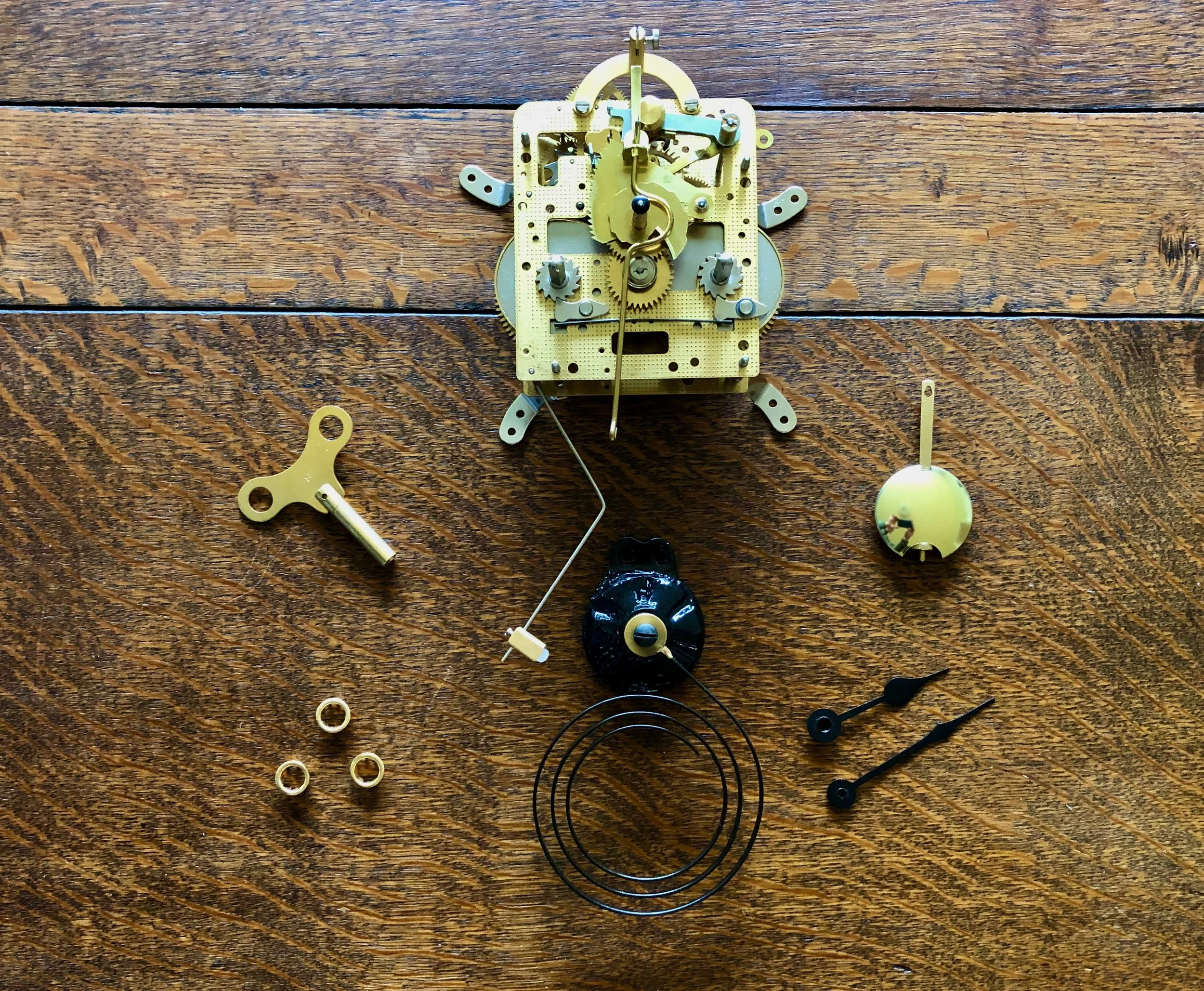

The rest of the materials are all metallic and mostly brass: the clock movement; pendulum; key; gong; grommets; hands and hinges. Everything but the hinges was procured from Clockworks, a terrific online clock parts store. Primarily serving the clock repair trade, they carry all manner of high quality horological goodies. Also, their informative website and live technical support are extremely helpful to the amateur clockmaker.

Clock components

Dimensioning

The clock case would be made from 3/4 in. boards, whereas the backboard, door and face would use thinner material. These thicknesses were created using the appropriate power tools and the mill marks then removed by hand before making the joint cuts. Like Stickley, I decided to use through tenons to fasten the bottom of the case, but opted for finger joints, rather than dovetails, for the top corners. Both finger and dovetail joints look beautiful when finished and, admittedly, both are overkill for this stress-free construct. However, finger joints would let me try something new and they also keep the shape repertoire for this elemental design down to two (circles, rectangles, trapezoids). But before I could cut the finger joints I needed a new jig.

Finger joint jigs come in several forms depending on whether you wish to create the joint using a router or table saw and, although commercially available, I prefer the homemade versions. Jigs for the table saw can be created by tinkering with a cross cut sled or by modifying the saw’s miter gauge. I opted for the table saw miter gauge version and, specifically, that jig described in a recent library book sale find, The Accurate Table Saw by Ian Kirby. Basically, this jig provides a mechanism to smoothly pass a vertically-oriented board through a spinning dado blade. The critical element is a 1/2 in. wide block of wood (aka key) that is affixed 1/2 in. to the right of the blade slot. The joint is cut by repeated passes through the 1/2 in. dado blade as the board is “marched” rightward in 1 inch steps. It works great, is easy to make from shop scraps, and you can get the whole concept from the picture below.

Shop-made finger joint jig in action

The fingers were fashioned on the top and side boards, and I also found that a simple modification of this jig could be used to accurately cut the tenons in the floor board. These were then dry-fit to describe the enclosure. Next, the clock mechanism was assembled on a stand and placed within the “case” so that the floor height and other critical dimensions could be fixed. The mortice sockets for the floor and rabbets to accommodate the backboard were now ready to be fashioned. Figuring out how to attach the movement to the case would await the next dry-fit.

Clock movement mounted on a stand within the partial case assembly

Two mortices were cut (1/2 x 1 in.) on each side piece and then the tenons of the 3/4 in. thick floor piece were rabbeted to the correct 1/2 in. depth for a snug fit. Next the backboard was constructed by re-sawing a 4/4 butternut plank in two, thickness planing these pieces to 3/8 in., edge joining them together and then trimming this “new” board to the final width and length. A rabbet was then created along the back edge of the four case components to house the backboard. The design of this particular clock movement requires that it be mounted to the back of the case. The clock and backboard would then be secured to the case sides by screws to facilitate its removal for servicing of the mechanism over time. However, attaching the clock directly to the backboard would place the clock hands too “deep” within the cavity and so a square piece of 1/2 in. plywood was affixed to the inside to act as both a shim and a stiffener to prevent warp. A small cove cut into the bottom of the plywood allowed the gong to nestle into its proper place. The clock movement was screwed to the center of this board and then the entire construct attached to the dry-fit case using brass, pan-heads.

Movement and gong temporarily mounted in place

With the movement mounted in its final position the pendulum was attached and mock doors were cut from cardboard to help visualize how the different circular openings would work. In this design, a circular opening in the door creates the clock “dial” and, due to the chosen case width, this circle must be centered at a point 3 3/4 inches from the top and sides. Located 4 3/4 inches directly below this coordinate would be the center of the pendulum, and a smaller circular cut-out was proposed to serve as a window on its movement. The diameters of these circles were the design variables in play. The hands selected for this clock serve a 6 inch face, and a circular cut-out of this size would be the largest feasible opening in a 7 1/2 inch wide door. I liked the boldness of going to the max here. Below this, the pendulum bob could be nicely framed within a 2 inch opening and so a mock door with a cut-out of this dimension was tried first. Result: too large; too much underlying commotion. Next, to focus solely on the pendulum bob, a 1 inch diameter hole was tried. Result: too small; too distracting. I could have kept experimenting with other diameters but based on the first two results I was now concerned that any opening here would only detract from the beauty of the clock as an object. I then tried a mock door without any pendulum window. I liked how this version celebrated the proportions of dial opening to door mass and then I recalled the “thou shalt not distract …” motto. Decision: forgo the window; let wood do the work!

Mock clock doors

To make the door, the remaining butternut was re-swan at the band saw and subsequently thickness planed to a 5/8 in. depth. This was then chopped, jointed, ripped, glued and smoothed (all with great care) to create a slightly oversized door panel ready for the circle cut. A similar sized board was created from the leftover “end cuts” to serve as a test subject for this crucial procedure. To fashion the circle, I decided to use an adjustable circle cutting device at the drill press. This “cutter” consists of a bit that fits into the drill chuck and serves to register the center of the desired hole. Attached to this bit is an adjustable arm that holds a sharp piece of steel which spins along the desired circumference, thereby scribing a circle into the wood as the drill press is lowered. During the test run I found it was difficult to dig more than halfway into the board without the cutter continually seizing up. To remedy, I removed the board from the drill press, completed the central hole puncture with a hand drill, flipped the board over and re-mounted the circle cutter with precise alignment using this hole as the guide. The remainder of the cut on this “backside” proceeded as before and just as the knife began encountering difficulty it broke through. The result was a nice clean circular edge on both surfaces with a fuzzy “rind” of rudely severed fibers left in between. The rough parts were knocked down using sandpaper to create an acceptably circular hole. Cutting and sanding the “real” door in this manner proceeded without incident. Finally the sides of the door were shaved with a hand plane to achieve the desired fit within the frame.

Cutting the “dial” on the drill press

To complete the case I needed only to: 1. shape the legs; 2. mount the clock face board; and 3. create mortices for the door hinges. The legs were easily fashioned from the side boards by drilling two 1 1/4 in. holes along the bottom edge at the drill press and then trimming the resulting “isthmus” at the band saw. For the clock face I wanted wood of a color that would both harmonize with the butternut case and also allow the black hands to be easily read at a distance. I chose some antique curly maple left over from the Stationery Chest Project for this. Its subtle character fits in nicely and could either be left bare & light or dyed some interesting shade, TBD. The chosen board was thickness planed to 5/16 in., smoothed and then cut to size. The tricky part is drilling holes for the hand shaft and winding arbors at the proper positions. Happily, upon request, Clockworks was able to provide the numerical spacings for these elements, as direct measurements on the movement are difficult. Once the holes were drilled I was able to rout a shallow trough on the backside of the face, above the hand shaft, to allow the movement’s front-mounted suspension spring and pendulum leader to swing freely. Four spacers were then prepared from butternut scraps that can be attached to the interior sides during assembly. These will support the clock face at the proper distance from the movement. Finally, mortices for the brass hinges were cut into the door and case side using a chisel. This is always a tricky job for me, but with patience it appears that I managed to cut out just the right amount of wood this time.

Door and case morticed to receive hinges

Assembly & Finish

After disassembling the dry-fit case and clock components (all the while making notes on the proper order for their re-assembly) it was finally time for glue-up. The mortice & tenon joints at the bottom were an ideal fit, but the finger joints up top were on the tight side and so glue was applied sparingly there for fear of swelling the wood prior to closure. Anyway, the case came together nice and square. Once the glue was dry the slight finger and tenon protuberances were all planed smooth and the case was sanded to 220 grit. Final sanding of the door and backboard were also conducted at this time. The plywood spacer board was then glued and screwed to the backboard and, with this piece tucked temporarily into the case, the four spacers for the clock face were attached to the case sides with glue. Dry-fitting the face board at this point revealed an unexpected challenge. The pendulum on this clock swings in front of the mechanism, and the hook at the end of the leader on which the pendulum mounts arches outward from the shaft just enough for this “highpoint” to rub along the interior of the newly mounted clock face. Routing out a slot, as for the suspension spring above, did not completely alleviate this friction source and so a 1/4 x 1 in. inch slit was cut out of the face to ensure the pendulum would swing freely. This slit is visible as a “feature” near the bottom of the dial, allowing a glimpse of the inner workings as the clock ticks away. Unplanned, but not unattractive.

On to the finishing steps. I liked the color of the butternut but would also be happy to see it darken over time. To assist the aging process, two applications of boiled linseed oil were applied (a 50/50 cut with mineral spirits, followed by a full strength coat) and after a couple days of curing, three coats of Arm-R-Seal wiping varnish were laid on over successive days. I used the satin sheen version of this product and find that it adds just enough life to the finish without tempting glare. The maple clock face, sanded to 400 grit, was finished with wiping varnish only. On test pieces I had played around with a couple dyes in the orange family. This color on the curly maple figure is stunning, but when placed behind the butternut door it made the clock appear disappointingly “artificial”. Good idea, but for some other Project.

A typical furniture piece would be complete right about now, but clocks are special; they need to both look good and also operate properly. The clock mechanism operates just fine as far as accurate gear movement is concerned, that was assured at the factory. Getting the gong right is the clockmaker’s job and involves two operations: aligning the hammer strike; and adjusting the minute hand. The hammer can only be aligned once all of the clock components are in their final position and so the movement was screwed to the backboard one final time and then held upright with a wood clamp while the pendulum and minute hand were affixed. To align the hammer, the thin steel rod supporting the head is bent/twisted, as required, to obtain a solid and squarely hit strike onto the outer ring of the metal gong. After aligning the strike I was able to adjust the length of the arm via a set screw on the head and then nip off the extra section of rod with wire cutters. A strong, stately gong every half-hour was the pay-off. Finally, the clock needed to be calibrated so that these gongs occurred whenever the minute hand was either straight up or straight down. This involves the iterative adjustment of a “square-holed” bushing nestled within the minute hand, itself, so that when pointed straight up it matches the rotational orientation of the square shaft when the gong hammer is released. A couple rounds of bushing twists followed by minute hand twirls and this clock was singing on the beat.

Adjusting the gong

The rest of the assembly proceeded as follows: mount the clock face with care to center the stem and arbors within their holes; press-in the brass grommets; attach the door hinges; mount the clock hands; and finally attach the pendulum. I chose to wait until this point to select and then mount the door knob. Torn between a wooden or a brass knob I collected a couple versions of each and then waited to get a feel for the finished clock, with the hopes that the choice would become obvious. Choice: brass. I liked how this material combined with that of the hinges and grommets to complete the exterior look and somehow suggest that there’s more brass to be found within. The knob’s mid-century design also kept things simple and round. A pleasing finishing touch.

Clock of the Westies

Congratulations Julia and Spencer! Time to enjoy a wedding.

4 Drawers

Those of you following along from the early days will recall the Stationery Chest and might be wondering: “hey, what ever happened there?” Good question. The short answer is that, partially completed, it had been moved out of the workshop and was biding time in a spare bedroom while its maker tackled other Projects and gained experience. Those Projects have lulled and, fresh from a valuable tutorial in drawer building with the Ledger Chest, I was now anxious to finish off this piece and place it in our living room where it belonged. Here’s the story.

The carcass of this chest was completed in early 2021 following plans from a book on Korean furniture making. This Project was a good challenge for me, involving the rehabilitation of some beautiful but twisted curly maple lumber, as well as a foray into novel woodworking terrain, specifically the mitered dovetail and Korean swallowtail joints. The piece shows clear signs of not-yet-craftsman-like “craftsmanship” but I’m getting there. My hope is that a solid job on the drawers and some care with the finish will create a handsome and functional piece.

Design

The plan calls for “inset” drawers which is what will be made. The sliding mechanism for these drawers, not even contemplated until now, will be a platform created using small plywood boards affixed (out of sight) to the bottoms of the drawer partitions. Corner joinery is stipulated in the Korean language plans to be half-blind “fist” joints (aka dovetails) but here’s where I’ll go off-road. Never having made these joints before, I did not want to wade further(x4) into unexplored territory on this piece - it has seen enough already. It also turns out that, upon measurement, the drawer openings are “a tad askew” and that felt like trouble when trying to fit an uncompromising joint like the half-blind dovetail. In contrast, joinery used recently for the Ledger Chest drawers, the rabbeted half-dovetail, appeared to be forgiving in that dimension. It is a nice drawer joint and was the one selected here.

Note added in proof: I have looked up some old Korean cabinets in online auctions and have yet to find a dovetailed drawer - they are all butt jointed. Makes me think the literature contains revisionist methodology, but more research is required.

Materials

Aside from the maple carcass, we would need additional maple for the drawer fronts and some reasonable hardwood stock for the concealed drawer parts. While I had planned to use yellow poplar for the interior drawer components, I was “fresh out” of that wood. However, I did have a pile of “extra” hardwood scraps, accumulated over a couple years of project making. I decided to use some leftover African mahogany for the drawer sides. Why not? I came across a twisted mahogany board that would be difficult to work with as a furniture element but, re-sawn into thin planks and then chopped into 8 inch parts, this hard, well-behaved wood could serve nicely as drawer stock. Might be a good look, too. Baltic birch plywood would be used for the drawer bottoms.

Wooden parts to complete the Stationery Chest

Consistent with Korean form, the drawer handles used would be single hooked, so-called “drop” pulls. These handles are quite unassuming compared with the hardware typically used to set-off (if not define) Korean furniture, but they should work well here where curly maple has the starring role. I found some Asian designs at a new online source for me, Ansaldi Furniture Hardware, which carries a wide selection of brasses. They seem solid and have just the right look. The design I had chosen for this chest is a variant of what Koreans call the “heavenly peach” and apparently this was the most commonly used handle for men’s stationery chests.

Heavenly Peach drawer pulls, in brass

Dimensioning

A piece of antique curly maple, the same as that used for the carcass, would form the drawer fronts. After removing decades of dusty accretions with a belt sander the 3 ft. long hunk was jointed flat on one edge, re-sawn into a pair of thinner planks and then jointed/thickness planed to a final width of 3/4 in. These beautiful boards will be used in a book matched orientation for the drawer fronts. (Although, since the pivot was on the short axis, it seemed more like “straight razor” matching.) To the extent that the finished grain shows its character, this should create an attention-grabbing, 56 inch flow across the entire front of the piece.

The drawer fronts were chopped to rough width, labelled 1-4, and then custom fit into their individual cavity openings. As mentioned previously, these openings were all about a degree off from 90 and so the sides of the drawer fronts needed to likewise conform with these slants. Now, hand planing along the end grain of wood is tricky business and so to create the new edge I found it easier to mark a line on the drawer front parallel to the cavity opening and then perform the angled cut along this line with the sliding miter saw. This saw comes equipped with a laser that casts a red beam directly below where the cut will occur. No need to measure angles, just align the laser with the pencil line and saw. I refer to this technique as “power fitting” and it may take a few centuries before it can be considered a traditional method. (Of course, by that time lasers are doing both the marking and the cutting, saw blades having become obsolete.) Anyway, it works pretty well today and it rapidly facilitated the nesting of all four drawer fronts.

Drawer fronts fitted to their cavities

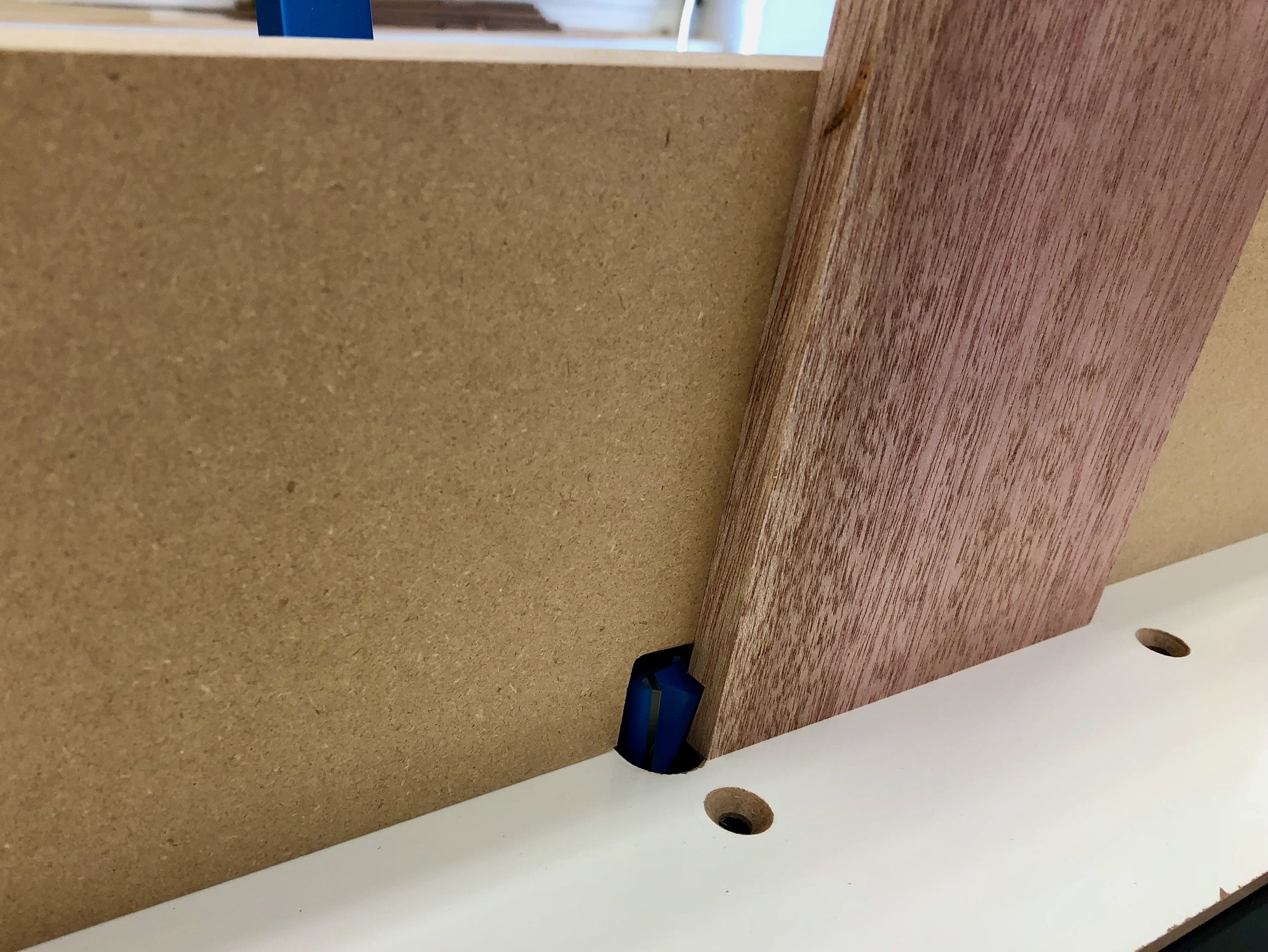

Next, I needed to create the sides, backs and bottoms of the drawers - 16 pieces, in all. This was done essentially as described for the Ledger Chest in episode 2 and need not to be recorded here. However, I did make one improvement worth noting. The half dovetail cut at the router table for the side pieces involves a vertical board orientation, where the end grain is slid along the table’s surface as the cut is occurring (illustrated below). That “surface”, surrounding the router bit spinning @ 23,000 rpm, is made up of a melamine table top, aluminum router plate and a circular plastic collar. As these materials do not abut smoothly, the resulting bumps, even though minuscule, are enough to make for a troublesome cut and a rough looking result. To eliminate this source of imperfection, I fashioned an auxiliary table top out of a small piece of dry erase board stock which allowed the mahogany boards to slide through the cutting bit with ease. Good solution with many more applications to come!

Mahogany drawer side being cut by a dovetail bit while sliding on the white auxiliary table top

Assembly & Finish

With a few hand plane strokes and some sanding, the labelled, dry-fit drawer constructs were methodically “futzed” into their cavities until they all operated as intended and a reasonably uniform gap pattern was achieved along all of the edges. The drawers were then disassembled and re-assembled with glue and clamps. Once dried, hardwood dowels were used to pin the front corner joints and the sides were then re-sanded smooth.

Fully assembled drawers

Finally, the carcass needed to be finished. That started with addressing the dovetails. The end grain portions of both the pins and tails stood somewhat “proud” of the joined surfaces (oh well, at least one of us was proud). While not uncommon in this type of joint, these protrusions would need to be leveled prior to the final sanding. Cutting lightly with a sharp block plane, they were slowly whittled down to “flat”. The sides and top were then smoothed with an orbital sander, progressing through a 120/150/220/400 grit sequence to make it look shiny-clean. Next I tried a technique for finishing “inset” drawer fronts that I read about in the handy reference book Building Doors & Drawers by Andy Rae. To begin, the carcass was flipped onto its back and small felt pads were affixed to the backside of the cabinet interior. These pads touched the rear of the drawers so that when fully inserted their faces peeked just proud of the frame. Sighting down the surface now reveals the topographic undulations of drawer front and frame elements which would be corrected in the following manner. The drawers were wedged tight within their opening using softwood shims and then the entire surface was worked carefully with the orbital sander using a 150/220/400 grit progression. Once everything was smoothed to satisfaction the shims were knocked through to liberate the drawers. Not perfect, but much better than the original state. The empty carcass was then flipped upright and all of the right-angled edges were “broken” using sandpaper to achieve a soft feel while retaining a sharp look.

The final step was to apply the finish. I had experimented earlier on a sample board where portions were first treated with either: 1. de-waxed shellac; 2. linseed oil; or 3. wiping varnish, followed by two coats of wiping varnish over all sections. It seemed the curly maple grain was highlighted nicely in every case, with the linseed oiled portion taking on a noticeably oranger hue compared with the others. Over time, that oiled portion would likely darken faster than the other two segments but that was not my goal on this piece. I was seeking to do right by the curly wave patterns in the wood and it looked like the Arm R Seal wiping varnish beat-out the shellac in this instance. Three coats of wiping varnish were then applied, with some minimal sanding in between and a buff job at the end, to finish the wood. Installation of the heavenly peach drawer pulls at last completed the Korean Stationery Chest, a good learning Project for me and a fine addition to our living space.

A Bluebird Home

I took a couple days in between furniture Projects to make a new bird house. Here’s the story.

Of all the delightful songbirds of New England, the Eastern bluebird (Sialia sialis) is my favorite. Not as charismatic as the feeder birds, not as regal as the robin, nor melodious like the wrens, bluebirds are, hands down, the most handsome. Of course, all of these descriptors are human-defined attributes that we project onto the creatures sharing our world. That’s okay if it helps us to appreciate their existence, and the valuable niches they inhabit alongside of our own. My wife and I enjoy promoting an environment where wildlife, and in particular birds, can thrive through the cultivation of native plants (aka weeds) in our gardens, augmenting the understory shrubs to create border sanctuaries, and by permitting much of our backyard to become an un-mowed meadow. Providing water sources and housing also helps to sustain an amazing variety of birds on our property: 44 different species have been recorded to date; 12 of which are verified nesters. As it turns out, bluebirds are especially reliant on human-made houses for they require a cavity, such as a hollow tree, in which to build their nest, and available cavities are scarce. Decaying trees tend to be removed before they can fall and cause property damage, and the hollowed ones that remain are hot commodities for a wide range of birds and mammals. Bluebirds hardly stand a chance. We have 2 bluebird houses in our yard that have hosted their namesake families, as well as chickadees, house wrens, tree swallows and (ahem) house sparrows over the past two summers. They are each booked 2 or 3 times during the busy season of April through July and also serve as a shelter for many species over the winter months. One of these structures had developed a crack in the roof board and upon closer inspection was generally rotting away. Time to build a new house!

Design

Birdhouse design follows some rather strict dimensional constraints that vary depending on the species you seek to accommodate. The entrance hole diameter, height of that hole above the floor and the inside floor dimensions are key. Fortunately, these parameters have been worked-out empirically for all of the box-nesting birds and you can find them listed in many reference books and websites. The remaining house features are secondary and, in general, less is best. For this bluebird house there will be nothing cute or gingerbread. No perch, no paint. In addition to the appropriate “box”, the proper habitat and height above the ground are important factors for nesting success. Bluebirds like to be out in the open and about 5 feet off of the ground - easily done. Two distinct bluebird house designs have evolved over the years and you have probably seen them both if you look about roadside fields and fence lines. I have chosen the simpler of these in an attempt to duplicate (with improvements) the house that I am replacing. The plan comes from an amazing book found for $1.00 at the annual Harvard, MA library book sale: Woodworking for Wildlife by Carol L. Henderson. This beautifully illustrated and informative work was produced by the State of Minnesota, Department of Natural Resources, specifically funded by the proceeds from that checkbox on the State’s tax forms. Hunh?! Anyway, I will be following their crystal-clear plan which “… may be reproduced for non-web educational purposes only.” Sorry. Just get the book, you’ll like it!

Materials

The beauty of this birdhouse plan is that in can be constructed entirely from a 1 in. x 6 in. x 6 ft. long piece of lumber, provided you make no mistakes along the way. I bought an 8 footer. Their box is fastened by nails, but I will use steel screws to match the expected longevity of the rot-resistant Western red cedar wood.

Dimensioning

The box is constructed of six parts, all 11/16 in. thick and 5 1/4 in. wide (i.e., the actual dimensions of my nominal 1 x 6 board). That means five chops at the miter saw and a rip cut to narrow the floor board is the extent of “woodworking for wildlife” to be enjoyed on this one. Take it slow; make it last. There is also some drilling to create the entrance hole and floor drains which was accomplished at the drill press. A hand saw and hand held drill would also have done the trick, so if you have any tools, and are so inclined, I encourage you to make your version of this house and mount it somewhere before Spring comes.

House parts

Assembly

Assuming squarely cut materials birdhouse assembly is a matter of lining things up appropriately and then fastening the parts together. I started with the floor board which is elevated about 3/4 in. off of the “true” bottom to avoid moisture creep from the walls. The floor is attached to the front, back and left side walls with 2 screws per side. The right wall will hinge and thereby serve as an opening for nest inspection and clean-out. It was attached to the front and back by using two stainless steel pan head screws affixed near the top. These screws need to be co-linear for they serve as a pivot hinge. The left side was then screwed to the front and back to complete the cavity. The roof comes next. I had toyed with a pitched roof, similar to the old house being replaced, and had even cut the appropriate parts at a 10 degree angle to make this happen, but the dry-fitted structure looked somehow “uppity”, whereas, the flat posture appeared more “welcoming” (now applying human-defined attributes to the inanimate). And since shedding rain on a surface this small is secondary to the hunting perch function served by bluebird house roofs I re-cut the parts square and went with that form. After creating a small ventilation space between the top of the walls and ceiling the roof was screwed into place. I chose to countersink the screws connecting the body of the house and then filled these divots with cedar plugs to enhance the look, however, I kept the roof screws accessible, just in case it needed a replacement before the rest of the dwelling succumbed. Finally, a small screw hook was installed to act as a door latch and the house was then bolted to that rusty pole in the front yard. A couple hours later we spotted a happy bluebird couple beginning to establish their squatter’s rights.